900 Series Standard Options:

Optional Main Beam Lengths (BXXX):

Main Beams may be ordered in any length between Trunnion Interface Mounts within the limits shown below. “XXX” = length in inches between trunnion interface mounts (1″ increments).

| MODEL | MIN | MAX |

| 961 | 46″ | 364″ |

| 989 | 69″ | 332″ |

Lengths longer than MAX shown above require a special beam.

While the two End Frames can be adjusted toward each other to accommodate smaller length parts, excessively long beams with a small part will leave the Main Beams extending from each End Frame enough to be inconvenient. It therefore is desirable to order the main beam close to the size of the actual part-to-be-handled.

Standard Combination Mounting Plate / Angle Clamp (P15 / A36):

2. Mounting Plate Interface (P15) – The Part-to-be-handled can be easily bolted to this flange type interface. The standard size is 11″ x 15″ with an eight-hole bolt pattern spaced at 13.5″ x 6″ centered on the plate. The eight holes will accept up to ½” diameter bolts. The standard finish is clear zinc plate.

Optional Index Plate (INDSXX):

The standard Index Plate is indexed @ 15 degree increments to prevent trunnion rotation with a lock pin. Optional Index Plates can be supplied at special increments as required by the customer. The two Index Stops can be bolted into any of the index holes in the Index Plate to prevent rotation beyond a desired point. This is desirable if your part-to-be-handled has a protrudance that could hit the main beam or floor or other obstacle when rotated beyond a certain orientation.

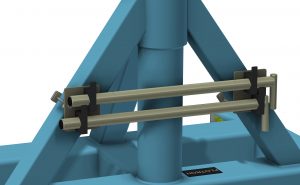

Optional Leveling Jacks (J0, J2):

4 bolt-on Leveling Jacks allow for leveling of load while in a stationary position. Code J0, which is not shown, is for jack mounting plates only but does not include Jacks. The J0 option allows for future addition of Jacks. Code J2 includes Jacks. The Jacks have 1″ of rise for each 14.6 turns of the crank handle.

Optional Fixture Finishes (N), (C):

1. Electroless nickel plating (N): This option replaces all zinc-plated parts with either electroless nickel-plated parts or stainless steel parts.

2. Clean Room option (C): This option is identical to the (N) option but with the addition of electroless nickel-plating on the interior of the end frame slide tubes and vertical support tubes. The exterior of the gearbox as well as the exterior of the end frames are painted with high gloss urethane or epoxy paint in place of the standard textured enamel paint.

Optional Ground Lug and Drag Chain (E):

For use in electrostatically protected areas (EPA’s). Proper electrostatic discharge (ESD) grounding of the fixture must be a part of the overall EPA design. (See technical section discussion on ESD)

Optional Lubricants:

Krytox GPL 207 (L1) – The trunnions and caster swivel bearings are lubricated with Krytox GPL 207. Note that this lubricant comes standard on “C” (Clean Room) finish and does not need to be specified.

Braycote 601EF (L2) – The trunnions and caster swivel bearings are lubricated with Braycote 601EF.

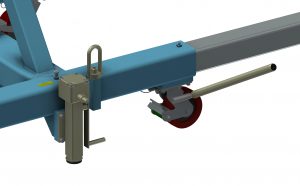

Push Bar (P1):

Vertical bars are mounted on the sides of each end frame to aid in pushing and steering the fixture during short intra-facility moves. The combination of having swivel locks engaged on the rear casters and bars for pushing and steering can make a huge difference to ease transportation. When the push bars are not in use, they can be lowered 18” so they are not in the way of assembly or test operations. The 900 series also comes with a standard towbar for transportation over longer distances. The frame mounted push bars can be retrofitted on existing Flotron Rotation Fixtures.

Optional Casters:

- (Blank) – Standard Ø8” X 3” wide urethane casters with brakes & swivel locks (no steering bars)

- (C1) – Ø8” X 3” wide urethane casters with steering bar receptacles, brakes and swivel locks. The kit comes with four steering bars and steering bar stowage features mounted to the end frames. It also comes with four push bar receptacles on the leveling jack mounting plates and the steering bars can be used as push bars.

Standard Proof Load Test (PLT):

Proof Load Test Procedure:

Dead weight load (no rotation), visual inspection

Static proof load test.

- Vertical load only.

- 200% vertical load, 100% torque.

- Hold load for 5 minutes minimum.

- Customer may witness test.

- Paint and plating covers all welds.

- Visually inspect for cracks, deformation, etc.

A deliverable proof load test report will be provided. The report will include a summary of the test procedure, actual measured weight of load applied, visual inspection results, and images of the test being performed.

Special Options:

If a standard Holding Fixture does not meet your requirements, contact Flotron about custom modifications. Often minor modifications to a standard unit are all you will need and can be done cost efficiently. See here for past examples of our Modified Standards and Custom Solutions.

For 900 Series – Creating a Model Number, click here.*