Jack Options:

Optional Finishes:

(Blank): Standard Finishes – Exposed jack components nickel plated. Stainless steel fasteners. Caster is zinc plated (if C2 option is chosen).

(C): Clean room – Clean room finishes – Same as standard finish with no zinc used on caster (if C2 option is chosen).

Optional Lubricants:

(Blank): Standard lubricant – Jack screw lubricated with Synco super lube grease.

(L1): Krytox LVP – The jack screw and caster swivel bearing are lubricated with Krytox LVP. All other bearings and gears are self-lubricating or sealed.

(L2): Braycote 631RP – The jack screw and caster swivel bearing are lubricated with Braycote 631RP. All other bearings and gears are self-lubricating or sealed.

Casters:

(Blank): No casters for Leveling jack (LJ models)

(C1): Standard mounting plate on bottom of jack for caster only (no caster provided – see

proposal drawing for mounting dimensions).

(C2): Standard Nylon caster with brake, and four position swivel lock.

See caster jack proposal drawing for caster size and other dimensions.

Leveling Foot:

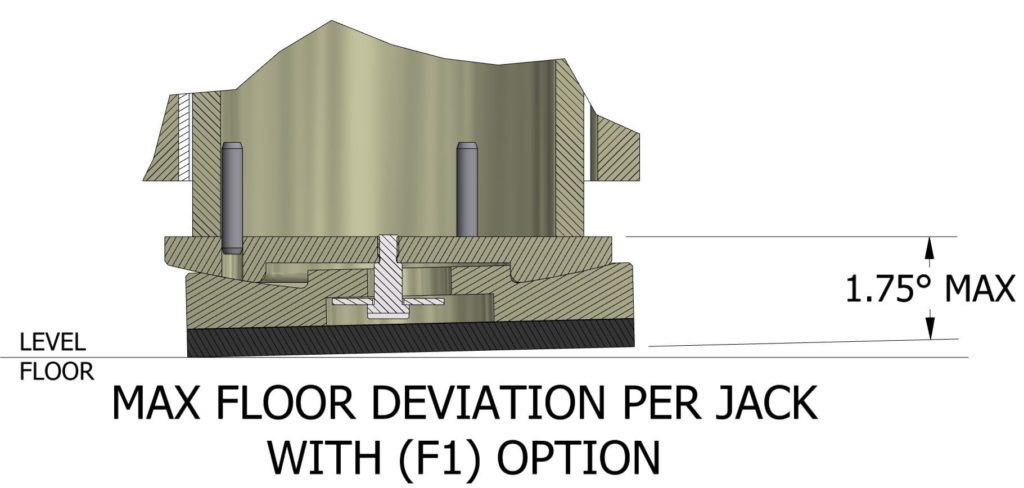

(Blank): Rubber pad on bottom of jack ram only. Pad accommodates 0.50° floor deviation per jack.

(F1): Leveling foot on bottom of jack ram for severely uneven floors. Leveling foot accommodates 1.75° floor deviation per jack. Optional for LJ-3750 & LJ-4500 models only (comes standard with LJ-8500).

Hand Crank Orientation:

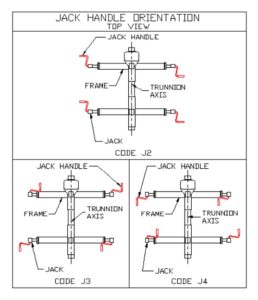

(J2): See jack handle orientation image below

(J3): See jack handle orientation image below

(J4): See jack handle orientation image below

Note: Orientation can be changed on-site by technician.

For LJ-3750, LJ4500, CJ-2500, and CJ3250 models: To change the orientation of the handle, remove the 8 mounting fasteners from the top cap and rotate the cap to the desired orientation in 45° increments. Once the handle orientation is set, simply re-install the fasteners.

For LJ-8500 and CJ-6000 models: To change the orientation of the handle, first remove the two fill/drain plugs on the top of the jack. Next, tip the jack upside down and drain all oil from the top cap. Once all the oil has been drained, remove the 8 mounting fasteners from the top cap and rotate the cap to the desired orientation in 45° increments. Once the handle orientation is set, re-install the top cap mounting fasteners and re-fill the jack with 9oz of Mobil SHC 634 oil using a funnel. Re-install the two fill/drain plugs.

Special Options:

If a standard jack does not meet your requirements, contact Flotron about custom modifications. Often minor modifications to a standard unit are all you will need and can be accomplished cost effectively. See here for past examples of our Modified Standards and Custom Solutions.

For Jack – Creating a Model Number, click here.*