SMS Series Options:

Optional ESD Package (E):

For use in electrostatically protected areas (EPA’s). Each mobile platform comes with banana plug receptacles and stainless steel drag chains to ground to a conductive floor (See technical section discussion on ESD for more information on grounding).

Optional Lubricants:

Krytox GPL 207 (blank):The leveling jack screws (if applicable) and caster swivel bearings are lubricated with Krytox GPL 207. Note that this lubricant comes standard and does not need to be specified.

Braycote 601EF (L2):The leveling jacks screws (if applicable) and caster swivel bearings are lubricated with Braycote 601EF.

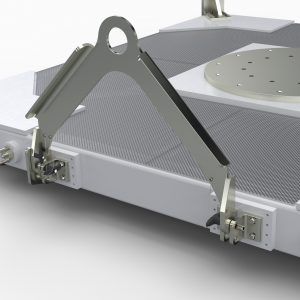

Optional Push Bar:

The push bar can be mounted to a utility pad on the base of the mobile platform, the push bar can be pinned at 30, 60, or 90 degrees to optimize the push height and maximize technician ergonomics. The push bar can be retrofitted to existing Flotron mobile platforms, only available for SM and MS sizes.

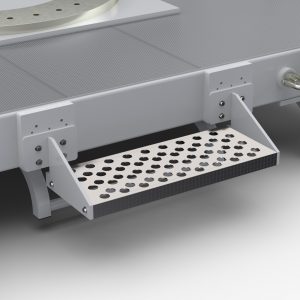

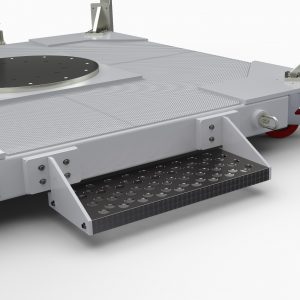

Optional Step:

The bolt on step allow technicians ergonomic access to the platform. The step can be retrofitted to existing Flotron mobile platforms, only available for SM and MS sizes.

Optional Mounting Interfaces:

Motorized Light Band (MLB) & ESPA Ring compatible interfaces, standard interface bolt pattern, or custom interface bolt pattern. Custom adapter standoffs also available.

Optional Towing Bar:

For the (T1), a removable towing bar is mounted to the utility pad on the mobile platform via two easily removable ball lock pins. The towing interface option can be retrofitted on existing Flotron satellite mobile platforms, only available for SM and MS sizes. For more dimensional information on the towing interface height ranges, see the proposal drawing.

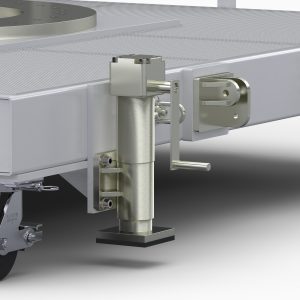

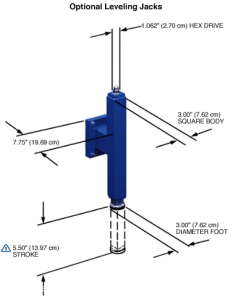

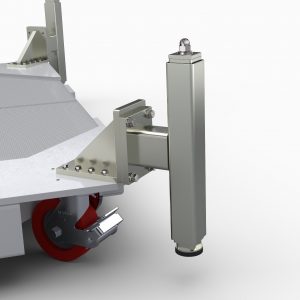

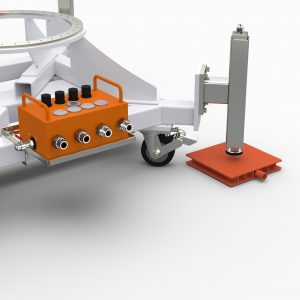

Optional Leveling Jacks (J0, J2, J5):

Code J0, is for jack mounting plates only but does not include Jacks. The J0 option allows for the future addition of Jacks.

Code J2 (MS only) is for bolt-on Leveling Jacks (Quantity of 4) allow for leveling of the payload while in a stationary position. Leveling Jacks have approximately 6” of stroke and 14.6 turns of the crank handle results in 1” of rise. The jacks come with removable hand cranks to prevent accidental rotation.

Code J5 is for Jacks which have a hex drive and a standard wrench (not supplied) can be utilized to crank up or down (SMS & SM only). The Jacks have a 5.5” stroke and 1″ of rise for each 10 turns of the hex drive.

Depending on which caster option is selected, the amount of ground clearance varies when the Leveling Jacks are fully extended or fully retracted. See the proposal drawings for more information.

Optional Casters:

(Blank): Standard Ø6” X 3” wide Phenolic wheel casters with brakes & swivel locks, Nickel finish caster body.

(AC): Air caster system option

(C1): Standard Casters with 6” diameter standoffs to swap in the place of the casters.

Standard Proof Load Test (PLT):

Proof Load Test Procedure:

Deadweight load, visual inspection

- Static proof load test.

- Vertical load only.

- 200% vertical load.

- Hold load for 5 minutes minimum.

- The customer may witness the test.

- Paint and plating covers all welds.

- Visually inspect for cracks, deformation, etc.

A deliverable proof load test report will be provided. The report will include a summary of the test procedure, the actual measured weight of load applied, visual inspection results, and images of the test being performed.

Special Options:

If a standard satellite mobile platform does not meet your requirements, contact Flotron about custom modifications. Often minor modifications to a standard unit are all you will need and can be done cost-efficiently.

For SMP Series – Creating a Model Number, click here.