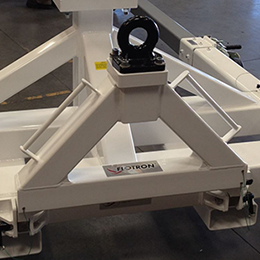

One of the special options Flotron offers for our Rotation Fixtures is a tow bar. The tow bar can be stowed up at near a 90 degree angle to the floor. By simply removing a clip, the tow bar can be lowered for attachment to a towing vehicle. If special tow bar requirements exist, Flotron can modify our existing tow bar designs to meet them.

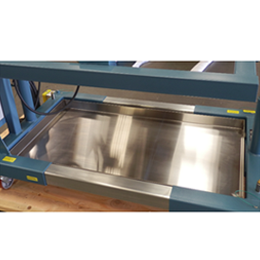

Sometimes customer payloads have the tendency to leak fluid in certain orientations and/or processes. Intentionally capturing and containing these fluids with our dip pans can prevent contamination, undesired contact with hazardous materials, or a slippery working surface.

Many Flotron fixtures with our standard finish have been successfully used in FS209E class 10,000 (ISO class 7) clean rooms. When specific customer Materials & Process requirements diverge from our standard finish option, we do have the capability to offer a modified standard solution. Common clean room related requests include our gloss white powder coat finish, substitution of electro-less nickel plated and stainless steel components for zinc plated and black oxide ones, and the use of clean room compatible lubricants like Krytox or Braycote.

Rolling surfaces and stability criteria vary between our customers and we have made an attempt to accommodate most customer needs with our standard off-the-shelf casters listed in our catalog and on our website. Some of our customers’ needs cannot be fulfilled with the standard casters and in these cases we would be happy to help identify a caster that is more suitable. We can provide casters with crowned geometries and harder wheel materials to maneuver heavy fixtures and payloads with less operator input, however this will increase rolling vibration transmitted to the customer’s payload when rolled over uneven surfaces. We can also offer dual-wheel or single wheel (foam-filled) pneumatic tire casters or spring loaded casters to roll over uneven terrain and maintain stability. We can also offer v-groove wheel casters to roll on a track system or high temperature casters that can sustain extreme thermal environments.

Flotron’s 1000, 1100 and 1200 series Rotation Fixtures are large standard predesigned units with load capacities ranging from 7,500 lbs – 14,500 lbs and torque ratings ranging from 46,900 in-lbs to 211,000 in-lbs. Flotron’s 1000 – 1200 Series Rotation Fixtures are supplied with heavy-duty stairstep resistant gearboxes to handle large, off-center loads which may occur during assembly of the mounted payload. These models are especially suited for large, heavy assemblies. See below for comparative data for the 1000 – 1200 series models and click on any of the images for additional information about a particular fixture.

Flotron’s 900 series holding fixtures are large, high load capacity standard predesigned units. They have roughly 2 times the load and torque capacity of the 800 series and are offered in two standard double beam configurations with adjustable riser heights. They are supplied with heavy-duty stairstep resistant gearboxes to handle large, off-center loads which may occur during assembly of the mounted payload. These models are especially suited for large, heavy assemblies. See below for comparative data on both 900 series models and click on either image for additional information about a particular fixture.

SFP-800 Series

Flotron’s Small Foot Print (SFP) 800 series Rotation Fixtures are a higher capacity, more compact version of the 800 series where floor space is a premium. The SFP-800 series includes additional features and options; lift points above the CG capable of lifting the Flotron (with the payload integrated), one inch of axial float on the non-gearbox side trunnion to ease payload integration, flat leg design to lower the rotation centerline height without sacrificing available payload swing radius, lighter weight to ease maneuverability, elimination of single failure points for launch site compatibility, PTFE composite sleeve bushings on the non-gearbox-side trunnion to eliminate exposed grease in this area, as well as an option for a cordless hand drill to rotate the gearbox. This series is offered in three standard single beam configurations with adjustable riser heights. They are supplied with heavy-duty, hollow shaft, stairstep resistant gearboxes to handle large, off-center loads which may occur during assembly of the mounted payload. See below for comparative data on the different SFP-800 series models and click on any image for additional information.

Flotron’s 700 series holding fixtures are standard off-the-shelf units and are offered in three models with single or double beam configurations & manual or assisted height adjustment. They are normally supplied with heavy-duty gearboxes to handle large, off-center loads during assembly stages. These models are especially suited for handling different types of spacecraft & aircraft assemblies along with other heavier parts. See below for comparative data on the different 700 series models and click on any image for additional information about a particular fixture.

SFP-600 Series

Flotron’s Small Foot Print(SFP) 600 series Rotation Fixtures are a higher capacity, more compact version of 600 series where floor space is a premium. The SFP-600 series includes additional features and options; flat leg design to lower the rotation conterline height without sacrificing available payload swing radius, lighter weight to ease maneuverability, as well as an option for a cordless hand drill to rotate the gearbox. See below for data on the SFP-600 series models and click on any image for additional information.

Flotron’s 500 series holding fixtures handle more weight and torque than the 400 series, while their footprint is basically the same. The HD525 has triple beam construction and the HD510 has single beam construction. The HD510-HYD model adds the feature of hydraulic height adjustment. This allows the height to be adjusted infinitely while your part is loaded rather than unloading the fixture to adjust height. The main beams are ordered to the length required for your parts. Telescopic beams are also available to handle longer parts. See below for comparative data on all the 500 series holding fixtures and click on an image for additional information about a particular fixture.