Archives

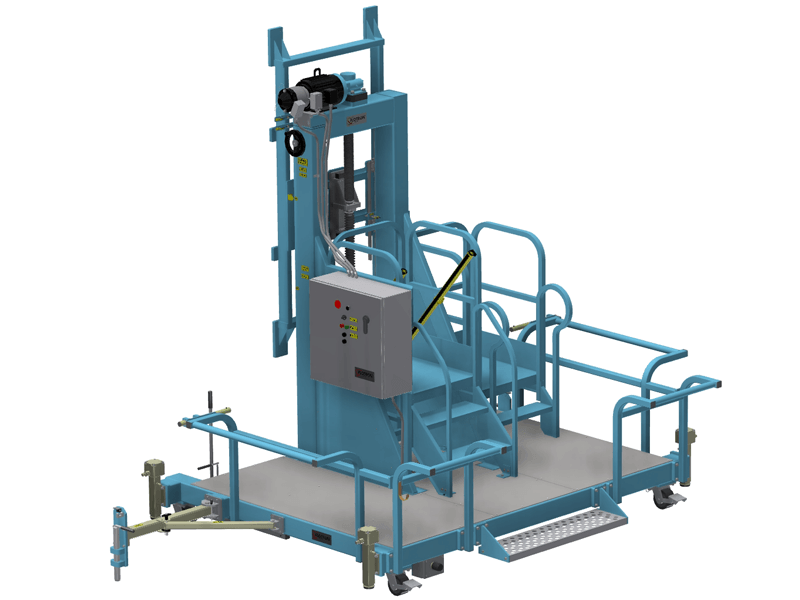

Engineered Lift

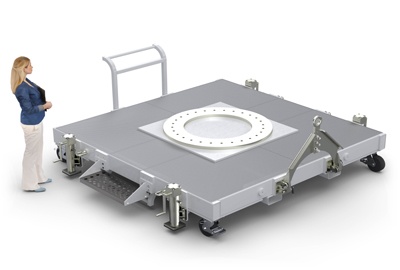

SMP-10000

Mid-Size Satellite Mobile Platform

The Mid-Size Satellite Mobile Platform shown below is designed to support mid-sized space vehicles that weigh 10,000 lbs and less and have a CG offset of less than 100” from the mounting interface. For more information, please visit the Mid-Size Satellite Mobile Platforms Options page and SMP-MS CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factor: 3.

- Rated Load Capacity: 10,000 lbs with CG located at 100” above mounting interface and 5” from the longitudinal axis.

- Operating Temperature: +32° to +104° F (0° to +40° C).

- Payload Interface: Ø48” plate with Ø40” bolt circle.

- Casters: Heavy Duty Ø8” x 3” phenolic or nylon wheels, electro-less nickel-plated finish with brake and swivel lock. (Optional air casters in place of wheeled casters are available)

- Materials: Steel Construction, clean room compatible.

- Finish: CLASS 10K clean room compatible finish – sky white powder coated base frame & push bar, electro-less nickel-plated interface plate, leveling jacks, tow bar and caster bodies (no zinc), stainless steel fasteners and miscellaneous hardware. The casters swivel bearings are lubricated with Krytox GPL207 and the unexposed leveling jack screws are lubricated with Synco Super Lube.

- Optional Tow Bar

- Optional Air Casters

- Optional Push/Pull Bar

- Optional Step

- Optional ESD package (banana plug receptacles & grounding wire)

- Optional Leveling Jacks

- For more about the Satellite Mobile Platform Options click here

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For SMP-10000 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

SFP-747

SFP-645

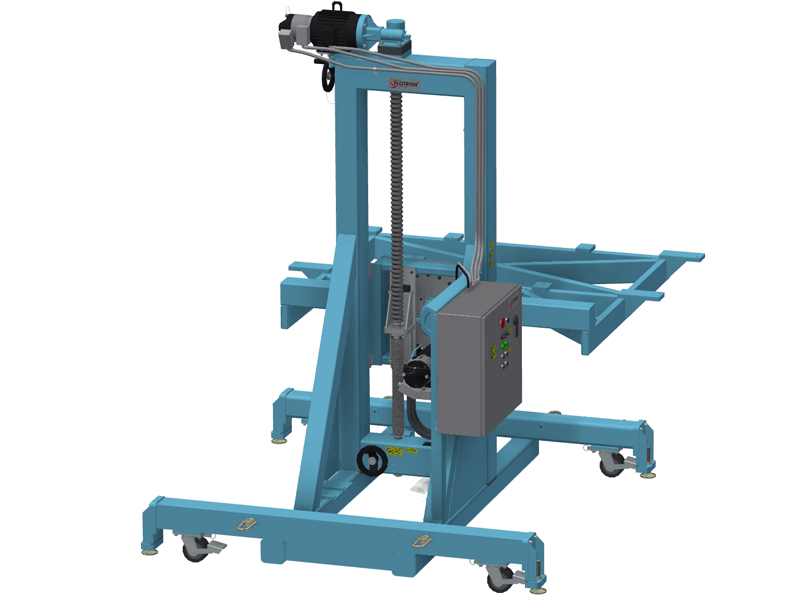

SMP-2000

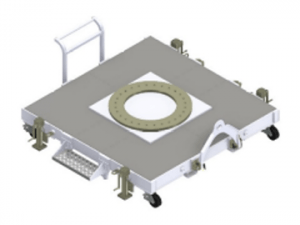

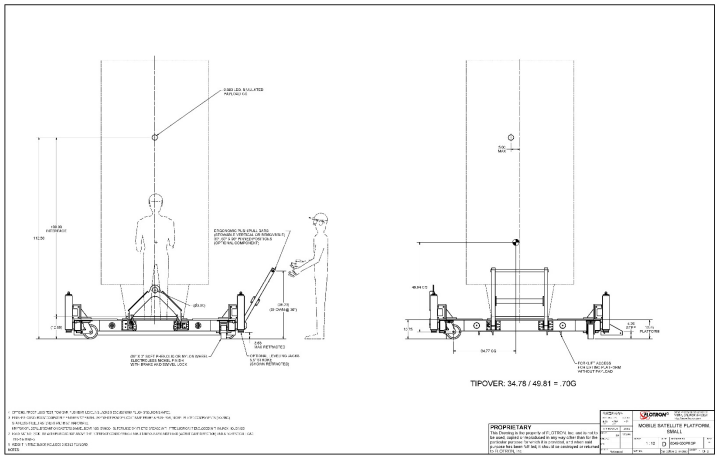

Small Satellite Mobile Platform Data Sheet

The Small Satellite Mobile Platform shown below is designed to support smaller space vehicles that weigh 2,000 lbs and less and have a CG offset of less than 100” from the mounting interface. For more information, please visit the Small Satellite Mobile Platforms Options page and SMP-SM CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factor: 3.

- Rated Load Capacity: 2,000 lbs with CG located at 100” above mounting interface and 5” from the longitudinal axis.

- Operating Temperature: +32° to +104° F (0° to +40° C).

- Payload Interface: Ø32” plate with Ø28” hole pattern.

- Casters: Heavy Duty Ø8” x 3” phenolic or nylon wheels, electro-less nickel-plated finish with brake and swivel lock. (Optional air casters in place of wheeled casters are available)

- Materials: Steel Construction, clean room compatible.

- Finish: CLASS 10K clean room compatible finish – sky white powder coated base frame & push bar, electro-less nickel-plated interface plate, leveling jacks, tow bar and caster bodies (no zinc), stainless steel fasteners and miscellaneous hardware. The casters swivel bearings are lubricated with Krytox GPL207 and the unexposed leveling jack screws are lubricated with Synco Super Lube.

- Optional Tow Bar

- Optional Air Casters

- Optional Push/Pull Bar

- Optional Step

- Optional ESD package (banana plug receptacles & grounding wire)

- Optional Leveling Jacks

- For more about the Satellite Mobile Platform Options click here

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For SMP-2000 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

SFP-655

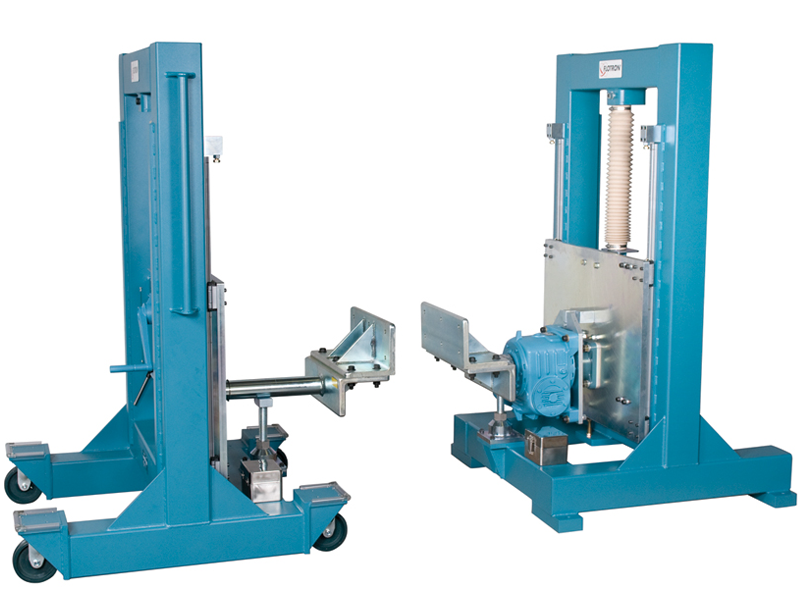

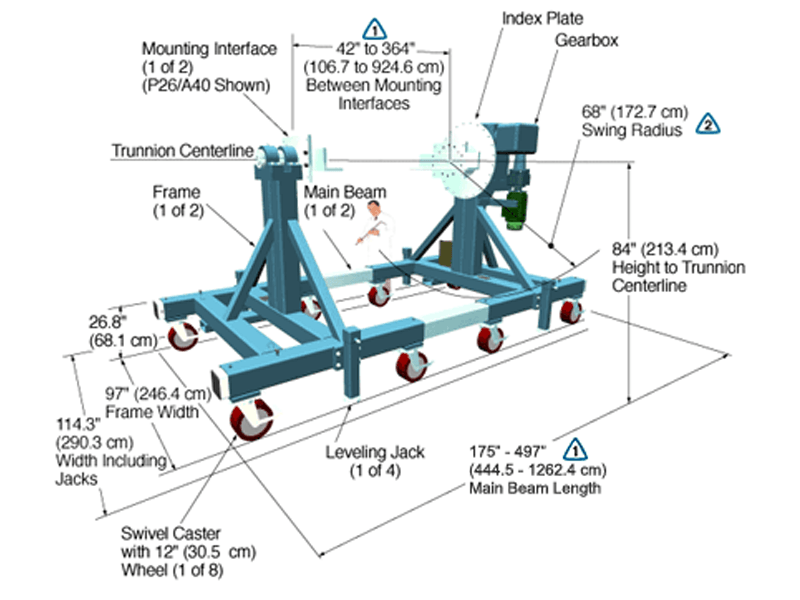

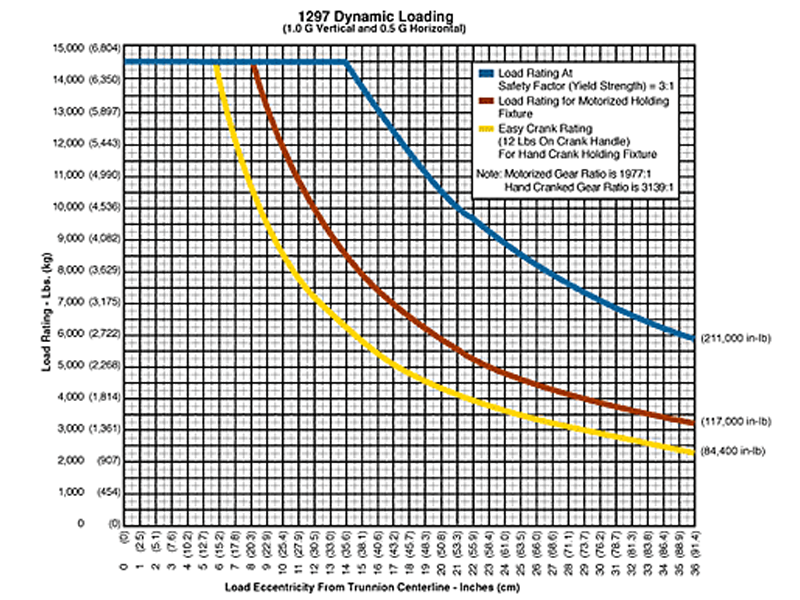

1297

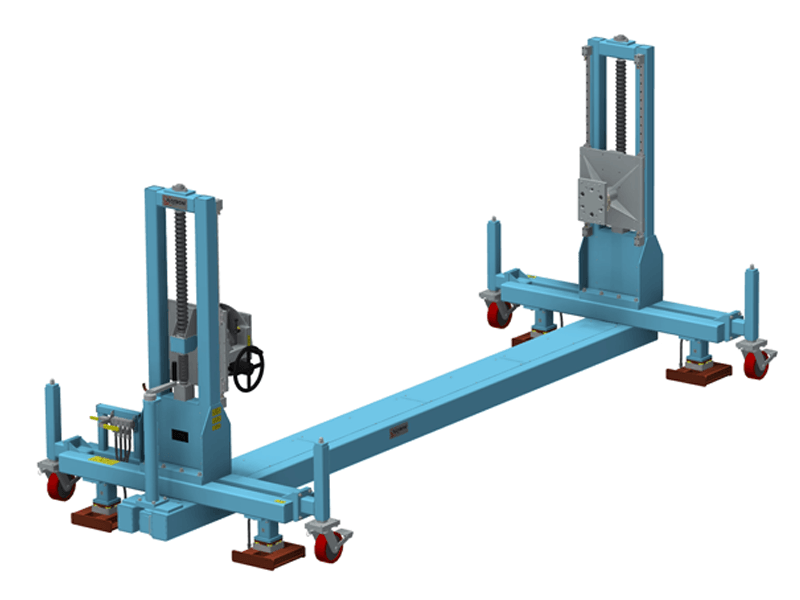

1297 Data Sheet

The Model 1297-J2-M-IND15-P26/A40-B080 shown below is typical and representative of the 1297 Models. To specify the correct model number for a specific holding fixture, see the 1200 SERIES OPTIONS pages and 1200 CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ to 7.5″ eccentricity: 14,500 lbs. (6,577 kg.)

- Dynamic, 21″ eccentricity: 10,000 lbs. (4,563 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Combination Mounting Plate / Angle Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beams

- Gearbox: Low backlash, non-backdriving stairstep resistant design with 1977:1 ratio

- Motorized Rotate Drive: The motorized, reversible rotate drive utilizes an inverter duty motor controlled by a programmable variable frequency inverter. Motor speed is reduced to output rotate speed through a multiple reduction, low backlash gearbox system which is designed to eliminate back driving and stair stepping. The maximum output speed is about 0.8 RPM and is controllable down to a minimum speed of about 10% of maximum speed. The motor and controls are designed for continuous operation in an open loop, four quadrant vector control mode. The controls, including circuit breaker, control transformer, braking resister, relays, etc., are enclosed in a NEMA 12 enclosure and the system is UL approved. A back up safety brake is included on the motor to prevent creep during motor off periods. A removable hand crank with safety electrical interlocks is provided for rotating the load in the case of an electrical malfunction.

- Self Aligning Couplings: These zero backlash couplings allow about ½ degree misalignment between load and fixture.

- Gearbox Hub: The zero backlash gearbox hub attaches the gearbox shaft to the index plate and mounting interface. The hub is designed to withstand both torque and overhung loads.

- Casters: 12″ diameter x 5″ wide wheel with polyurethane tread, kingpinless swivel bearing, brake and swivel lock

- Index Plate: Standard with 15° index plate and index stops

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius“.

- Optional Motorized Rotate drive with 1975:1 ratio gearbox and variable frequency motor control

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- Optional Main Beam lengths

- Optional Leveling Jacks

- For more about 1200 Series Options click here

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 1200 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

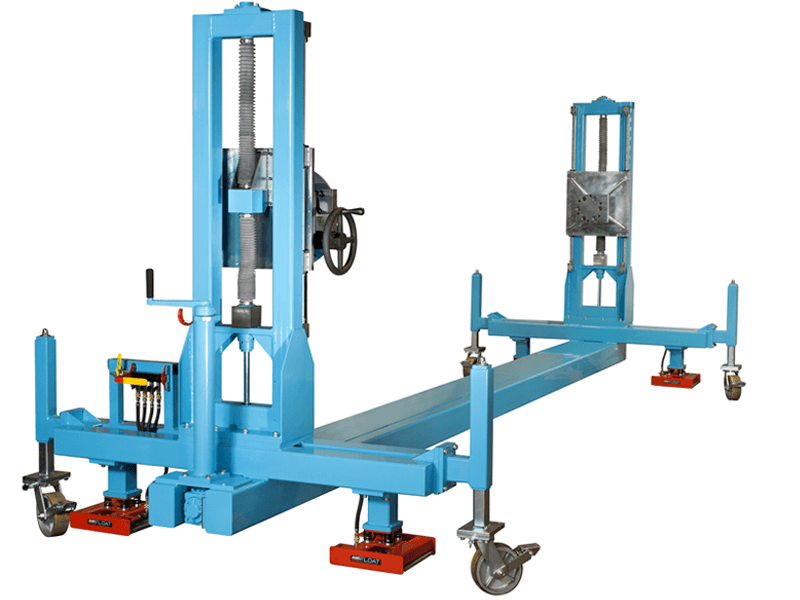

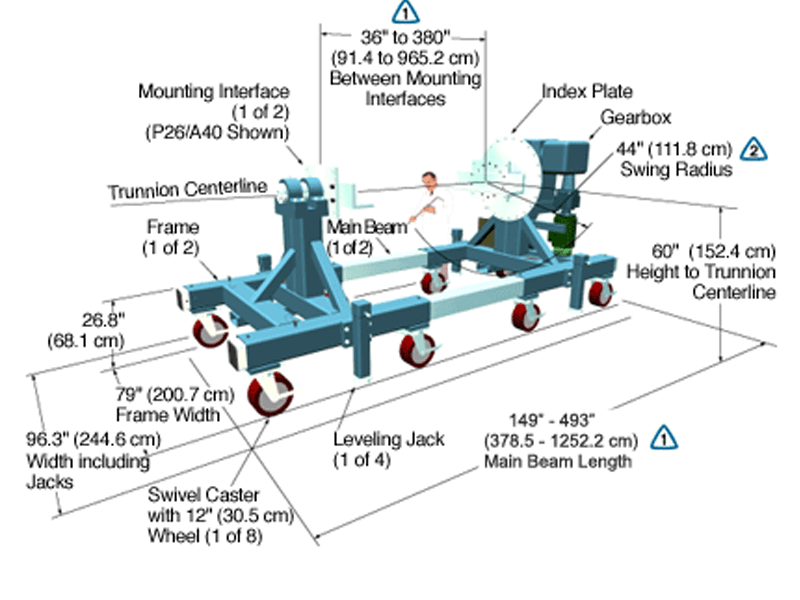

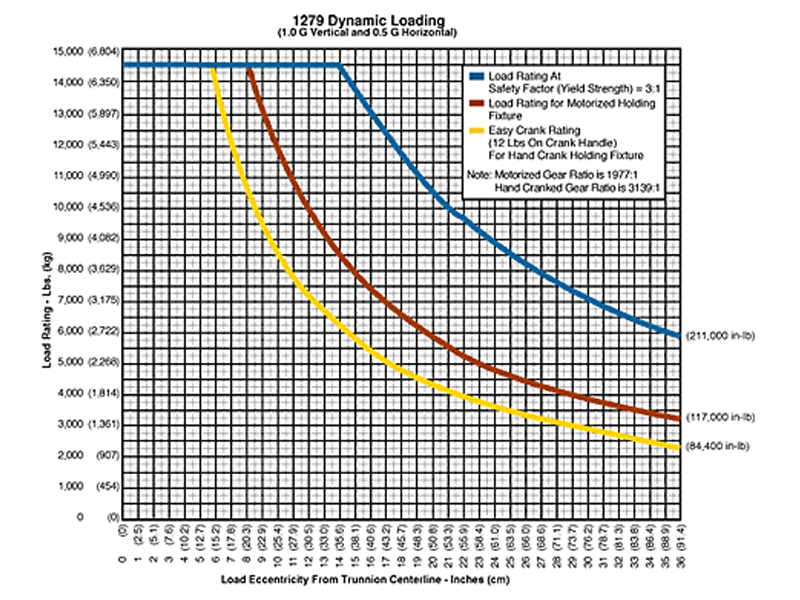

1279

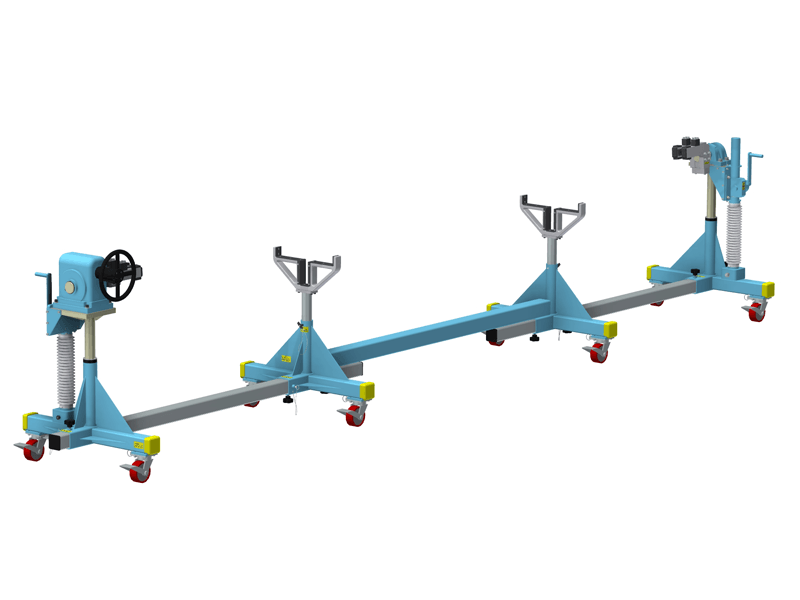

1279 Data Sheet

The Model 1279-J2-M-IND15-P26/A40-B080 shown below is typical and representative of the 1279 Models. To specify the correct model number for a specific holding fixture, see the 1200 SERIES OPTIONS pages and 1200 CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ to 7.5″ eccentricity: 14,500 lbs. (6,577 kg.)

- Dynamic, 21″ eccentricity: 10,000 lbs. (4,563 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Combination Mounting Plate / Angle Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beams

- Gearbox: Low backlash, non-backdriving stairstep resistant design with 1977:1 ratio

- Motorized Rotate Drive: The motorized, reversible rotate drive utilizes an inverter duty motor controlled by a programmable variable frequency inverter. Motor speed is reduced to output rotate speed through a multiple reduction, low backlash gearbox system which is designed to eliminate back driving and stair stepping. The maximum output speed is about 0.8 RPM and is controllable down to a minimum speed of about 10% of maximum speed. The motor and controls are designed for continuous operation in an open loop,four quadrant vector control mode. The controls, including circuit breaker, control transformer, braking resister, relays, etc., are enclosed in a NEMA 12 enclosure and the system is UL approved. A back up safety brake is included on the motor to prevent creep during motor off periods. A removable hand crank with safety electrical interlocks is provided for rotating the load in the case of an electrical malfunction.

- Self Aligning Couplings: These zero backlash couplings allow about ½ degree misalignment between load and fixture.

- Gearbox Hub: The zero backlash gearbox hub attaches the gearbox shaft to the index plate and mounting interface. The hub is designed to withstand both torque and overhung loads.

- Casters: 12″ diameter x 5″ wide wheel with polyurethane tread, kingpinless swivel bearing, brake and swivel lock

- Index Plate: Standard with 15° index plate and index stops

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius“.

- Optional Motorized Rotate drive with 1975:1 ratio gearbox and variable frequency motor control

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- Optional Main Beam lengths

- Optional Leveling Jacks

- For more about 1200 Series Options click here

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 1200 Series – Creating a Model Number pdf click here

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.