SFP-635-EML

Load Rating: 500 lbs

Swing Radius: 39.0"

Max Torque: 1,275 in-lbs

Easy Crank: 700 in-lbs

To receive a CAD model or a quotation:

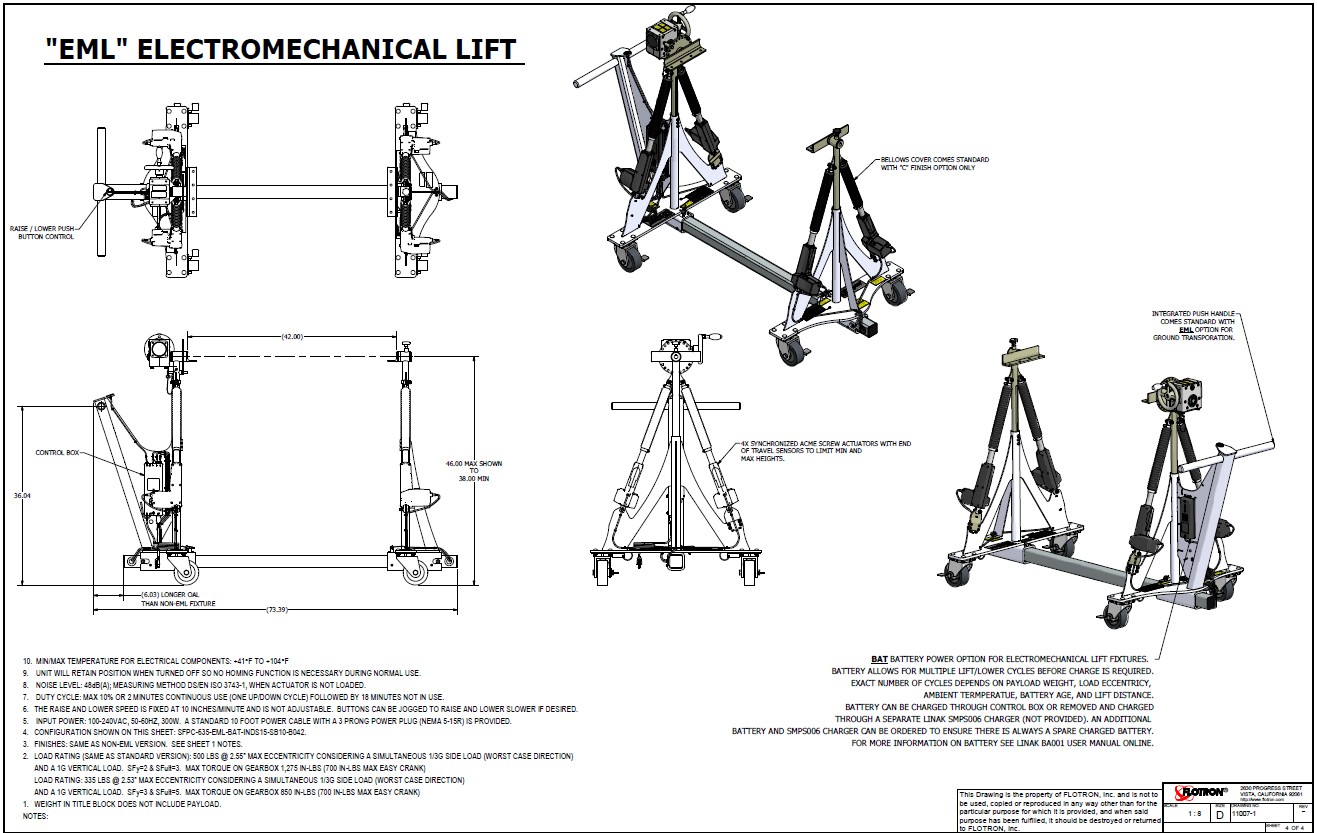

The electro-mechanical lift fixtures add the functionality of electrically operated and synchronized height adjustment during assembly, integration, and test activities. The system is plug and play and with a simple press of a button, the risers can adjust height while the payload is attached to the interfaces. This option has some advantages over hydraulics, requiring less maintenance and for compatibility in clean room environments. The system runs on 100-240VAC, 50-60HZ, 300W and uses a standard 3 prong power plug (NEMA 5-15R). The unit remembers position even when unplugged or turned off, so no homing function is necessary during normal use. Click on images below for more information.

Product Features

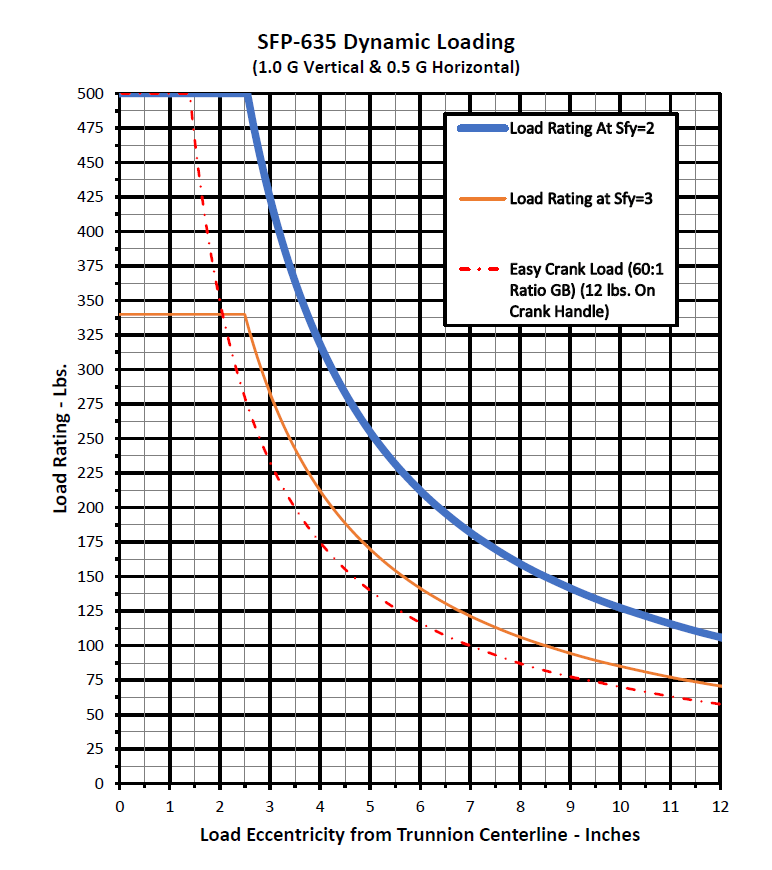

- Safety Factor: Sfy = 2 and SFu=3

- Rated Load Capacity:

- Dynamic, 0″ eccentricity: 500 lbs. (227 Kg.)

- Dynamic, 5″ eccentricity: 255 lbs. (116 Kg.)

- Operating Temperature:

+41°F to +104°F (0°C to +40°C)

- Contact factory for special applications with extended operating temperatures.

- Main Beam Ball Lock Pin: Secures position of end frames to main beam once the payload interface distance has been set.

- Materials: Steel construction

- Synchronized electromechanically controlled risers: The synchronized risers can adjust the height of the payload when it is attached to the trunnion interfaces. Pushing the up or down arrow on the control button causes the risers to raise or lower in unison. Unit will not lose position or need to be re-homed when powered off.

- 360° part rotation: The part can be rotated 360° to place the area to be worked on in an ergonomic location.

- Raise/Lower speed: 10 inches per minute (approximately 48 seconds to lift 8")

- Trunnion Brake Knob: A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

Standard Configuration (For additional options click on “Configure a Flotron Fixture” button above or view dimensional drawing for detailed information)

- Finishes: Flotron blue powder coated end frames; Gearbox painted Flotron blue; Zinc plated or black oxide fasteners, misc. hardware, and components; Standard lubricants.

- Main Beam: Single beam that connects the end frames.

- Gearbox: 60:1 ratio gearbox with a 6" diameter crank.

- Trunnion Interface/Mount/Clamp Options:

- Multiple interface choices available

- Trunnion Bearings: Steel on Steel trunnion bearing. Ideal for shorter payloads that are rigid.

- Choice of Interface "B" distance: Distance between interfaces. See proposal drawing for how angle interface distances are measured if angle interface is chosen.

- Casters: 5" diameter X 2" wide polyurethane wheels with swivel bearing and brake.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 600 Series - Creating a Model Number pdf click here

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.