Archives

SFP-655

SFP-635-EML

SFP-635

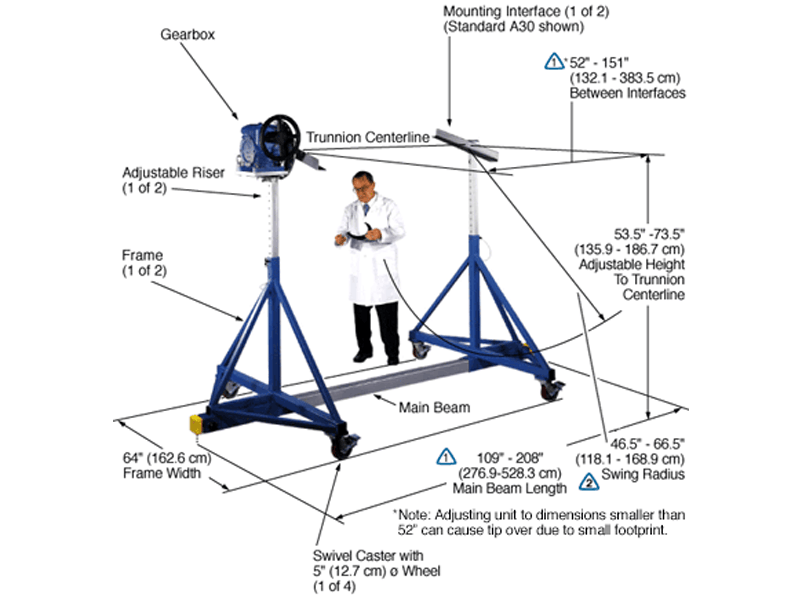

HD664

HD664 Data Sheet

The Model HD664-SR-IND15-A30-B063-C1 shown below is typical and representative of the HD664 Models. For more information on specifying a holding fixture, see the 600 SERIES OPTIONS page and 600 SERIES CREATING A MODEL NUMBER pdf.

* Note: Adjusting unit to dimensions smaller than 52″ can cause tip over due to small footprint.

Product Features:

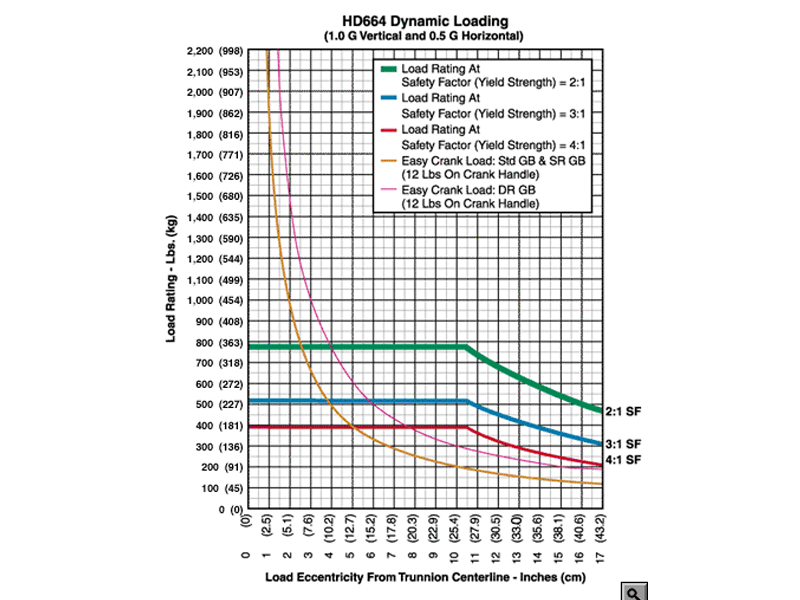

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ eccentricity: 520 lbs. (236 kg.)

- Dynamic, 5″ eccentricity: 520 lbs. (236 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Choice of Trunnion Interface/Mount/Clamp Options:

- Angle Interface

- Mounting Plate Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beam

- Gearbox: SR low backlash gearbox with 60:1 ratio & 12″ diameter crank

- Casters: 5″ diameter x 2″ wide wheel with polyurethane tread, sealed swivel bearing and Tech-lock brake

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

- Optional Main Beam Lengths

- Optional Trunnion Interface/Mount/Clamp

- Optional Index Plate

- Optional Index Stops

- Optional Casters

- Optional DR low backlash, stairstep resistant Gearbox

- Optional Split Pillow Block Trunnion Bearings

- Optional finishes for clean room compatibility

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- For more about 600 Series Options click here

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 600 Series – Creating a Model Number pdf click here

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

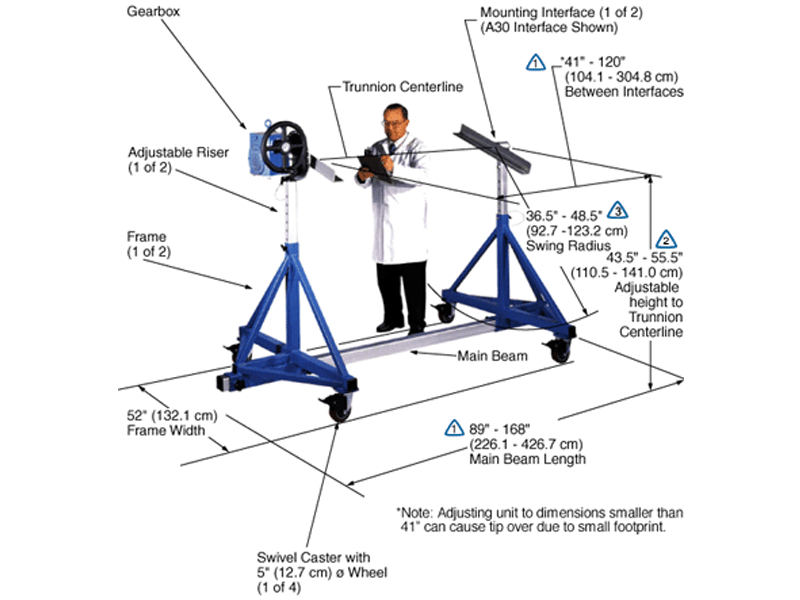

HD652

HD652 Data Sheet

The Model HD652-IND15-A30-B057 shown below is typical and representative of the HD652 Models. For more information on specifying a holding fixture, see the 600 SERIES OPTIONS page and 600 SERIES CREATING A MODEL NUMBER pdf.

A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”* Note: Adjusting unit to dimensions smaller than 41” can cause tip over due to small footprint.

Product Features:

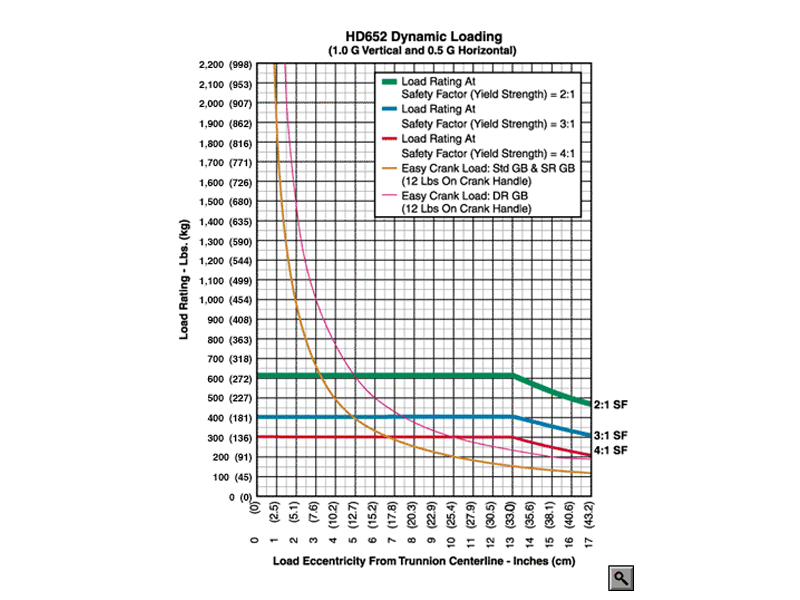

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ eccentricity: 400 lbs. (181 kg.)

- Dynamic, 5″ eccentricity: 400 lbs. (181 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Choice of Trunnion Interface/Mount/Clamp Options:

- Angle Interface

- Mounting Plate Interface

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beam

- Gearbox: 60:1 ratio with 12″ diameter crank

- Casters: 5″ diameter x 2″ wide wheel with polyurethane tread, sealed swivel bearing and Tech-lock brake

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

- Optional Main Beam Lengths

- Optional Trunnion Interface/Mount/Clamp

- Optional Index Plate

- Optional Index Stops

- Optional Casters

- Optional Gearboxes incorporating heavy duty, low backlash and stairstep resistant features

- Optional Split Pillow Block Trunnion Bearings

- Optional finishes for clean room compatibility

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- For more about 600 Series Options click here

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 600 Series – Creating a Model Number pdf click here

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

HD641

HD641 Data Sheet

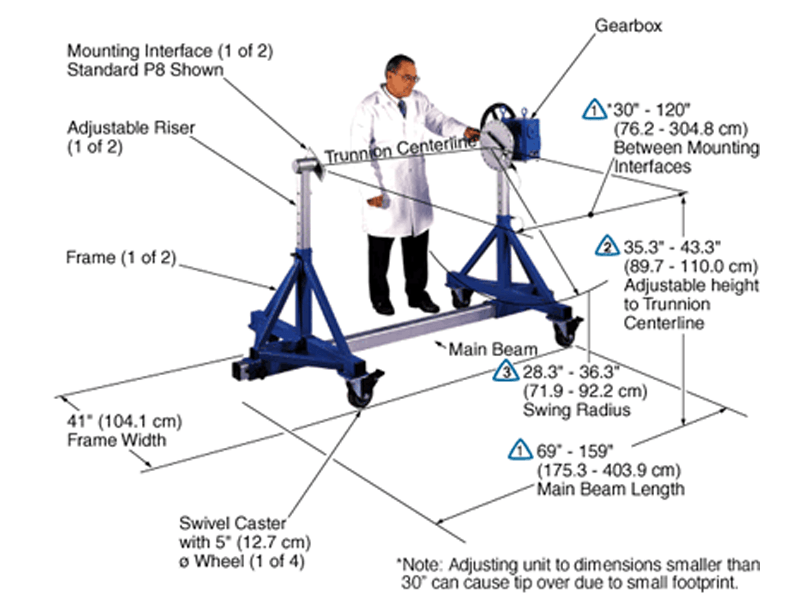

The Model HD641-IND15-P8-B045 shown below is typical and representative of the HD641 Models. For more information on specifying a holding fixture, see the 600 SERIES OPTIONS page and 600 SERIES CREATING A MODEL NUMBER pdf.

* Note: Adjusting unit to dimensions smaller than 30″ can cause tip over due to small footprint.

Product Features:

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ eccentricity: 760 lbs. (345 kg.)

- Dynamic, 5″ eccentricity: 760 lbs. (345 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Choice of Trunnion Interface/Mount/Clamp Options:

- Angle Interface

- Mounting Plate Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beam

- Gearbox: 60:1 ratio with 12″ diameter crank

- Casters: 5″ diameter x 2″ wide wheel with polyurethane tread, sealed swivel bearing and Tech-lock brake

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

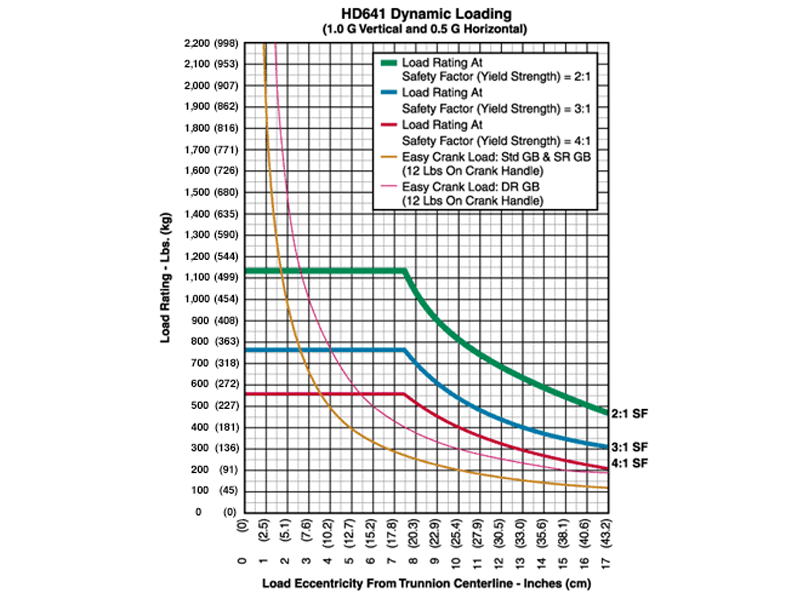

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

- Optional Main Beam Lengths

- Optional Trunnion Interface/Mount/Clamp

- Optional Index Plate

- Optional Index Stops

- Optional Gearboxes incorporating heavy duty, low backlash and stairstep resistant features

- Optional Split Pillow Block Trunnion Bearings

- Optional finishes for clean room compatibility

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- For more about 600 Series Options click here

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 600 Series – Creating a Model Number pdf click here

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.