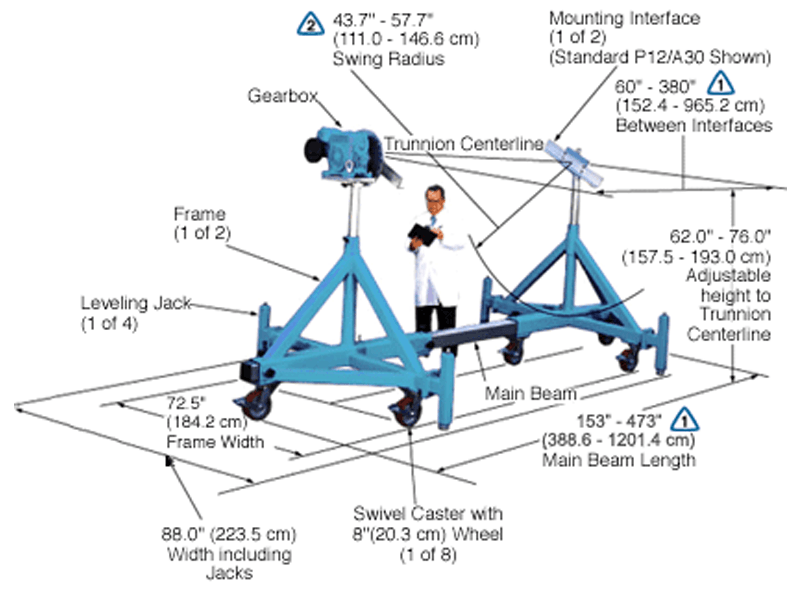

872 Data Sheet

The Model 872-J5-IND15-P12/A30-B104 shown below is typical and representative of the 872 Models. For more information on specifying a holding fixture, see the 800 SERIES OPTIONS page and 800 SERIES CREATING A MODEL NUMBER pdf.

The maximum distance between mounting interfaces is directly related to the main beam length. Specify the distance between mounting interfaces to be at or slightly larger than the length of the part-to-be-handled. The fixture can be adjusted to accommodate smaller length parts, however, the main beam(s) extending from each end frame may be inconvenient. For more information see the

800 SERIES OPTIONS page and

800 SERIES CREATING A MODEL NUMBER pdf.

A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

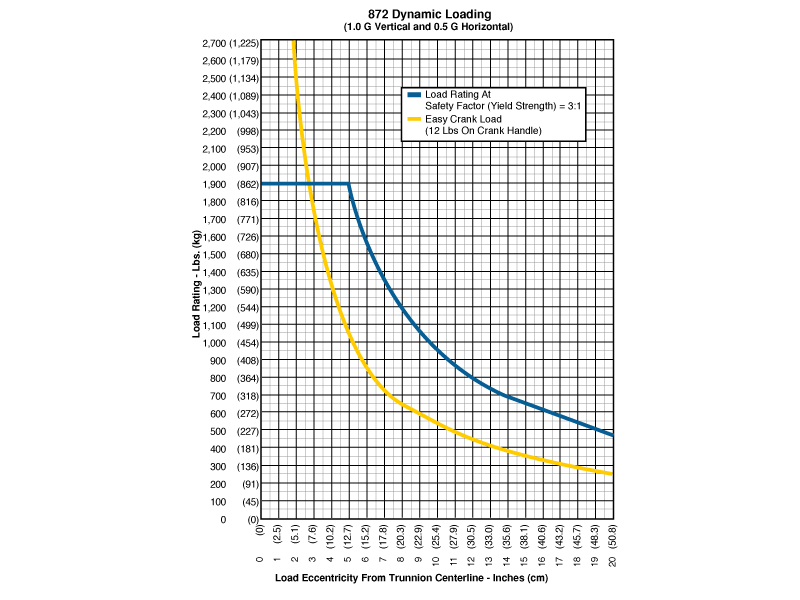

Product Features:

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ to 3.5″ eccentricity: 1,900 lbs. (862 kg.)

- Dynamic, 10″ eccentricity: 940 lbs. (426 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Combination Mounting Plate / Angle Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beam

- Gearbox: Low backlash, non-backdriving stairstep resistant design with 250:1 ratio and 8″ diameter crank

- Self Aligning Couplings: These zero backlash couplings allow about ½ degree misalignment between load and fixture.

- Gearbox Hub: The zero backlash gearbox hub attaches the gearbox shaft to the index plate and mounting interface. The hub is designed to withstand both torque and overhung loads.

- Casters: 8″ diameter x 3″ wide wheel with polyurethane tread, kingpinless swivel bearing, Tread Lock brake and swivel lock

- Index Plate: Standard with 15° index plate and index stops

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius“.

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- Optional Main Beam lengths

- Optional Leveling Jacks

- Optional finishes for clean room compatibility

- For more about 800 Series Options click here

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 800 Series – Creating a Model Number pdf click here.

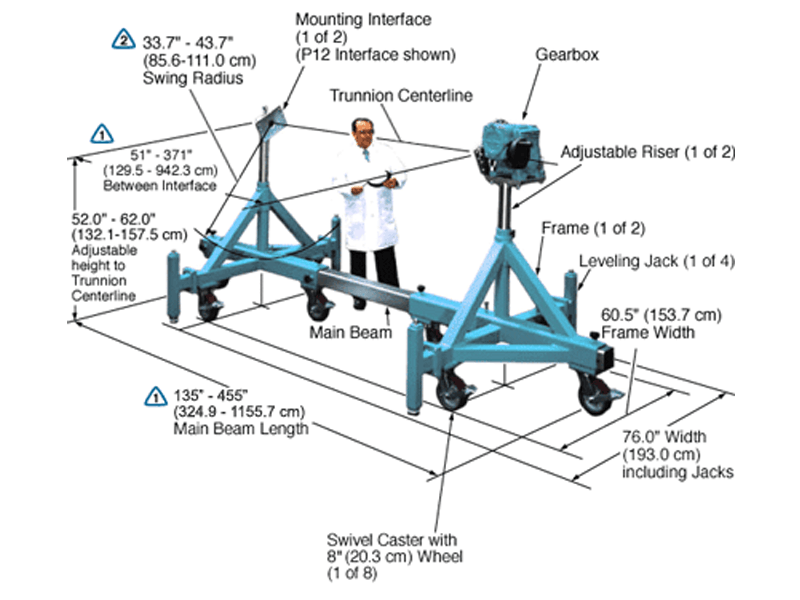

860 Data Sheet

The Model 860-J5-IND15-P12-B089 shown below is typical and representative of the 860 Models. For more information on specifying a holding fixture, see the 800 SERIES OPTIONS page and 800 SERIES CREATING A MODEL NUMBER pdf.

The maximum distance between mounting interfaces is directly related to the main beam length. Specify the distance between mounting interfaces to be at or slightly larger than the length of the part-to-be-handled. The fixture can be adjusted to accommodate smaller length parts, however, the main beam(s) extending from each end frame may be inconvenient. For more information see the

800 SERIES OPTIONS page and

800 SERIES CREATING A MODEL NUMBER pdf.

A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

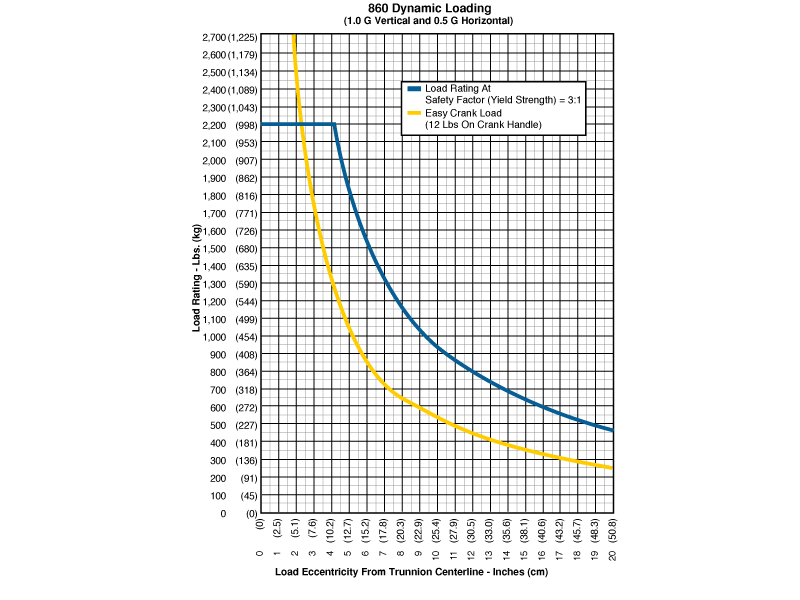

Product Features:

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ to 4″ eccentricity: 2,200 lbs. (998 kg.)

- Dynamic, 10″ eccentricity: 940 lbs. (426 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Combination Mounting Plate / Angle Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beam

- Gearbox: Low backlash, non-backdriving stairstep resistant design with 250:1 ratio and 8″ diameter crank

- Self Aligning Couplings: These zero backlash couplings allow about ½ degree misalignment between load and fixure.

- Gearbox Hub: The zero backlash gearbox hub attaches the gearbox shaft to the index plate and mounting interface. The hub is designed to withstand both torque and overhung loads.

- Casters: 8″ diameter x 3″ wide wheel with polyurethane tread, kingpinless swivel bearing, Tread Lock brake and swivel lock

- Index Plate: Standard with 15° index plate and index stops

- Materials: Steel construction

- Finish: Blue Paint or Powder Coat (at manufacturer’s discretion), with selected parts zinc plated. Other finishes available upon request

- Price Range: $38K – $64K

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- Optional Main Beam lengths

- Optional Leveling Jacks

- Optional finishes for clean room compatibility

- For more about 800 Series Options click here

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 800 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

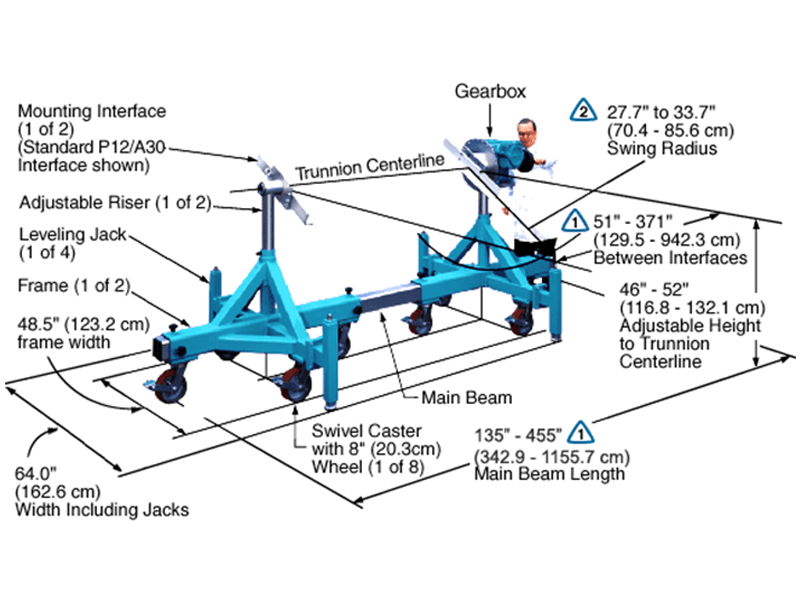

848 Data Sheet

The Model 848-J5-IND15-P12/A30-B074 shown below is typical and representative of the 848 Models. For more information on specifying a holding fixture, see the 800 SERIES OPTIONS page and 800 SERIES CREATING A MODEL NUMBER pdf.

The maximum distance between mounting interfaces is directly related to the main beam length. Specify the distance between mounting interfaces to be at or slightly larger than the length of the part-to-be-handled. The fixture can be adjusted to accommodate smaller length parts, however, the main beam(s) extending from each end frame may be inconvenient. For more information see the

800 SERIES OPTIONS page and

800 SERIES CREATING A MODEL NUMBER pdf.

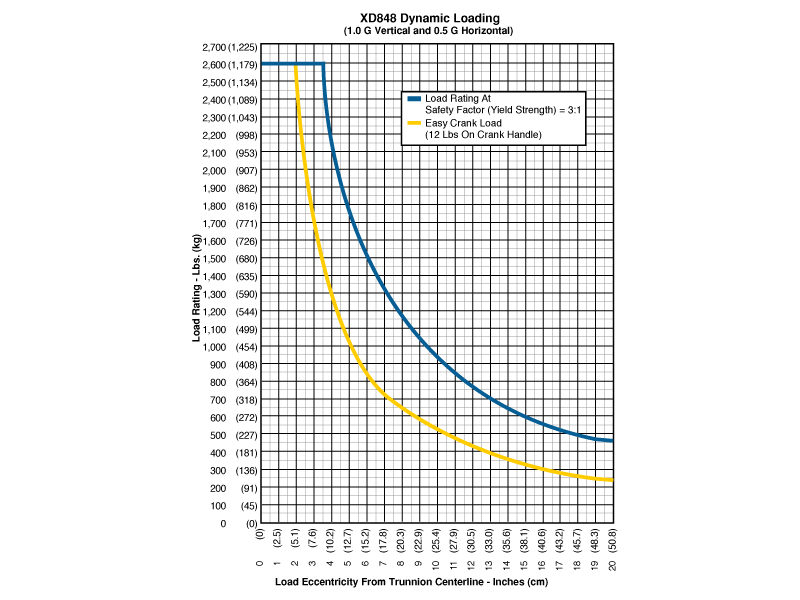

A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

Product Features:

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ to 3.5″ eccentricity: 2,600 lbs. (1,179 kg.)

- Dynamic, 10″ eccentricity: 940 lbs. (426 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Combination Mounting Plate / Angle Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beam

- Gearbox: Low backlash, non-backdriving stairstep resistant design with 250:1 ratio and 8″ diameter crank

- Self Aligning Couplings: These zero backlash couplings allow about ½ degree misalignment between load and fixture.

- Gearbox Hub: The zero backlash gearbox hub attaches the gearbox shaft to the index plate and mounting interface. The hub is designed to withstand both torque and overhung loads.

- Casters: 8″ diameter x 3″ wide wheel with polyurethane tread, kingpinless swivel bearing, Tread Lock brake and swivel lock

- Index Plate: Standard with 15° index plate and index stops

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius“.

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- Optional Main Beam lengths

- Optional Leveling Jacks

- Optional finishes for clean room compatibility

- For more about 800 Series Options click here

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 800 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.