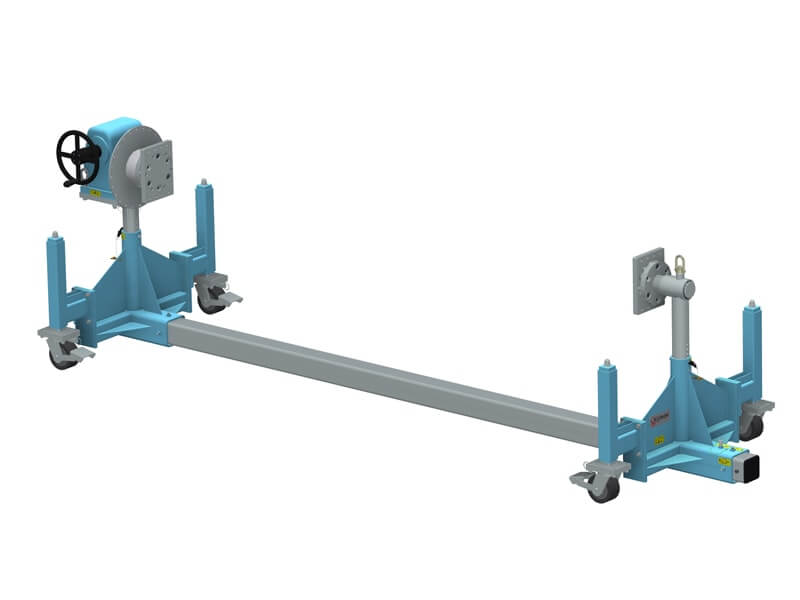

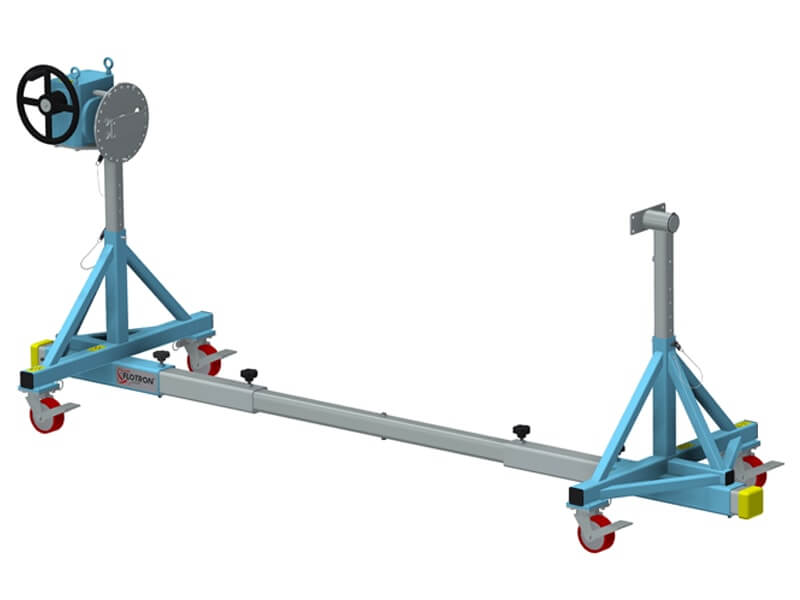

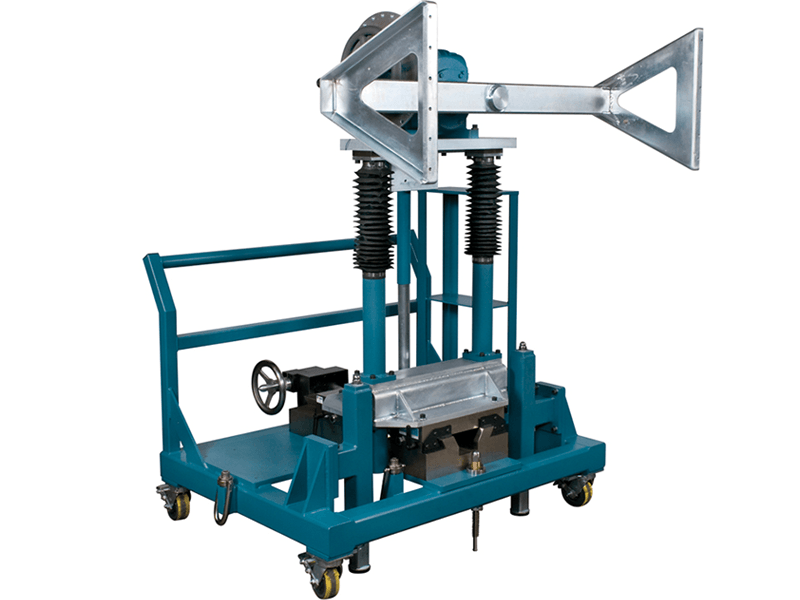

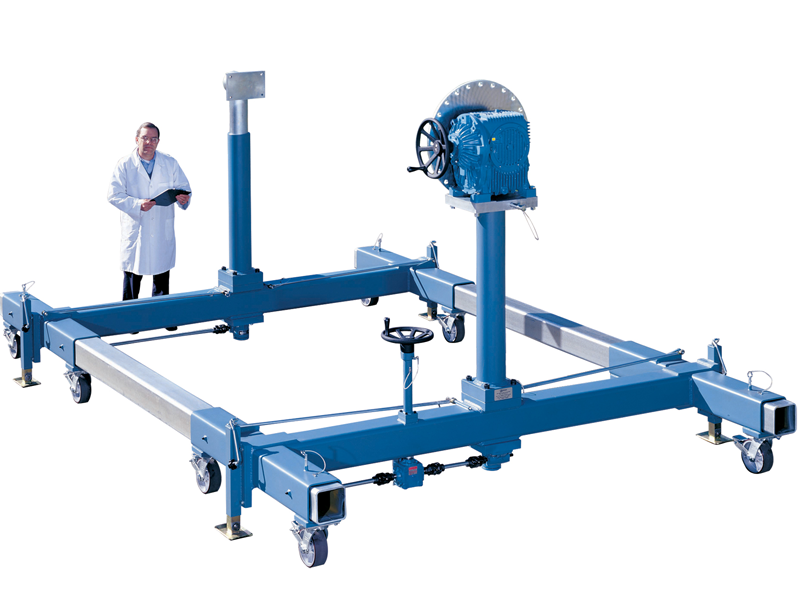

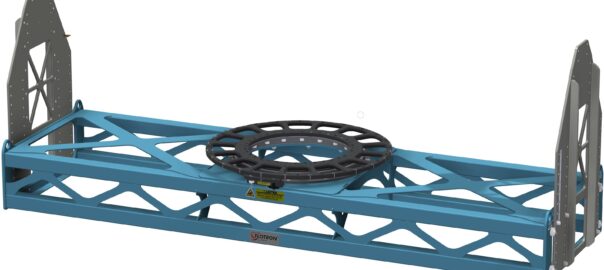

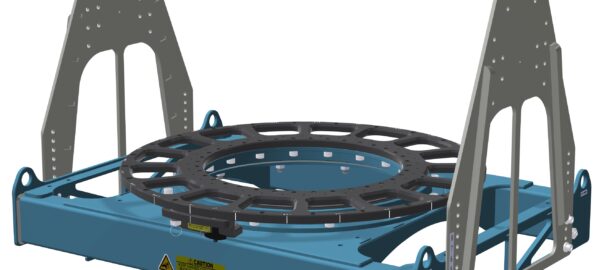

DSC-G2

(Gearbox Driven Interface)

Load Rating: 2,300 lbs Cantilevered 30” (See dimensional drawing sheets 3-6 for load curves)

Payload Max Swing Radius: 59”

Max Torque (Secondary Axis): 23,000 in-lbs

Product Features

- Safety Factor: 3 for Yield & 5 for Ultimate

- Rated Load Capacity: Dynamic, 0″ to 4″ eccentricity: 2,300 lbs. (1,043 kg.) Cantilevered 30” (762mm)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Materials: Steel and aluminum construction. Stainless steel fasteners.

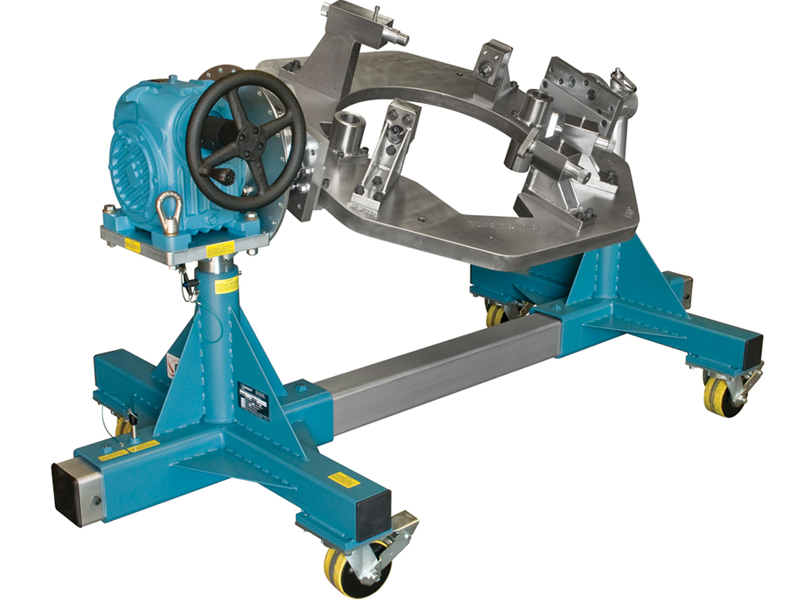

- Gearbox Driven Interface: Non-backdriving (self-locking) low-backlash gearbox rotates the interface via a hand crank. Interface can be pinned in 15° increments for redundant safety. 352 turns of handwheel for one full revolution of interface.

- Adjustable Interface Height: Eight bolt positions to ensure that payload CG is close to primary axis of rotation centerline. Four lift points integrated into frame for bolt position adjustment or for lifting empty cradle. Guide blocks included to facilitate adjustment.

- Optimized Design: Cradle analyzed with FEA to optimize design to be high capacity yet light weight.

Standard Configuration (For additional options click on “Configure a Flotron Cradle” button above or view dimensional drawing for detailed information)

- Finishes/Lubricants: Class 10k (ISO 7 cleanroom compatible finishes) – Cradle powder coated textured Flotron blue color; stainless steel hardware; aluminum parts chem film or hard anodized; Mobiltac 375NC (or equivalent) to all slewing ring teeth; slewing ring inner raceway lubricated with Mobilux EP2 (or equivalent). Fasteners lubricated with Loctite 242 blue or Krytox GPL 207. Gearbox sealed and pressure tested.

- Cradle Length: 120” Between Mounting Interfaces. (Special cradle lengths available in 20” increments from standard).

- Interface Bolt Pattern: ESPA Grande/MLB interface. 36X ¼-28 UNF threaded holes on a Ø24” bolt circle.

Load Rating: 2,300 lbs Cantilevered 30”

———————————————————————

Payload Max Swing Radius: 59”

———————————————————————

Max Torque (Secondary Axis): 23,000 in-lbs

———————————————————————-

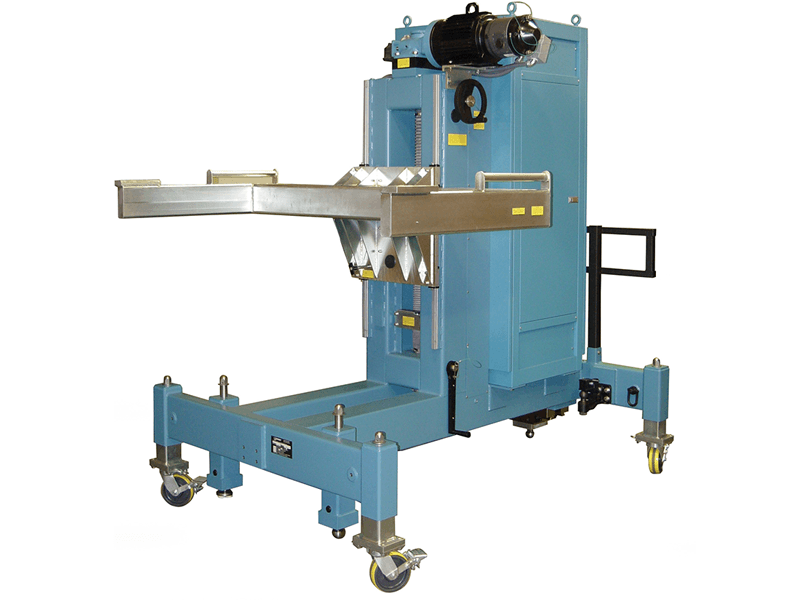

Load Rating: 2,500 lbs Cantilevered 30”

———————————————————————

Payload Max Swing Radius: 59”

———————————————————————

Max Torque (Secondary Axis): 10,000 in-lbs

———————————————————————-

Load Rating: 700 lbs Cantilevered 24”

———————————————————————

Payload Max Swing Radius: 29”

———————————————————————

Max Torque (Secondary Axis): 10,000 in-lbs

———————————————————————-

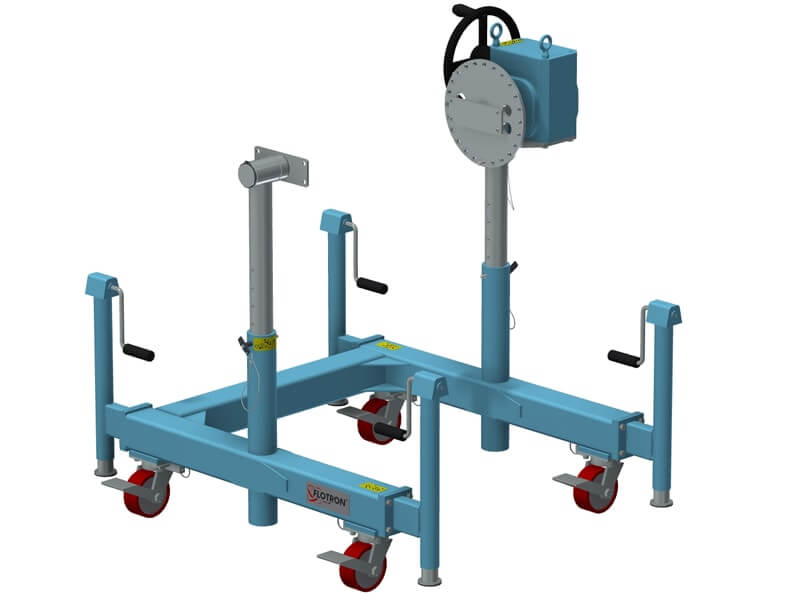

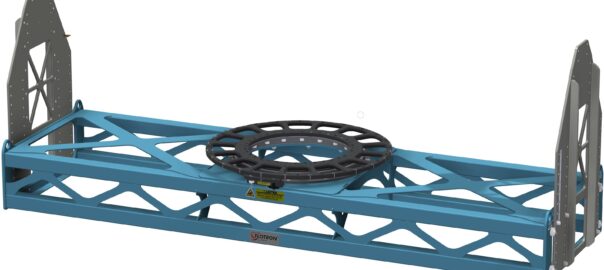

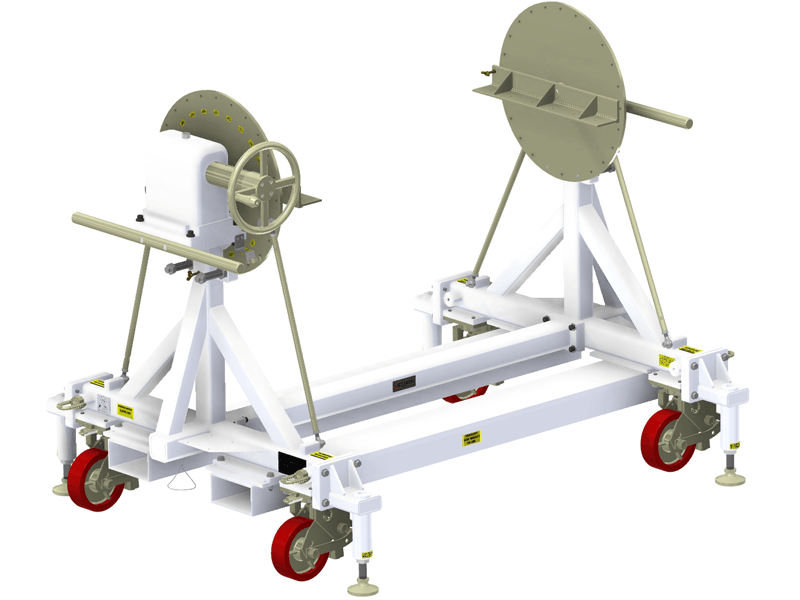

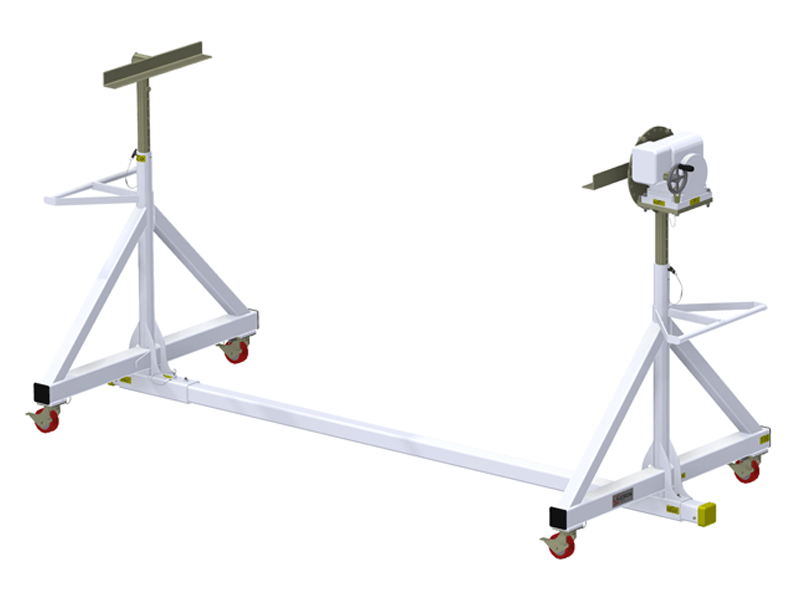

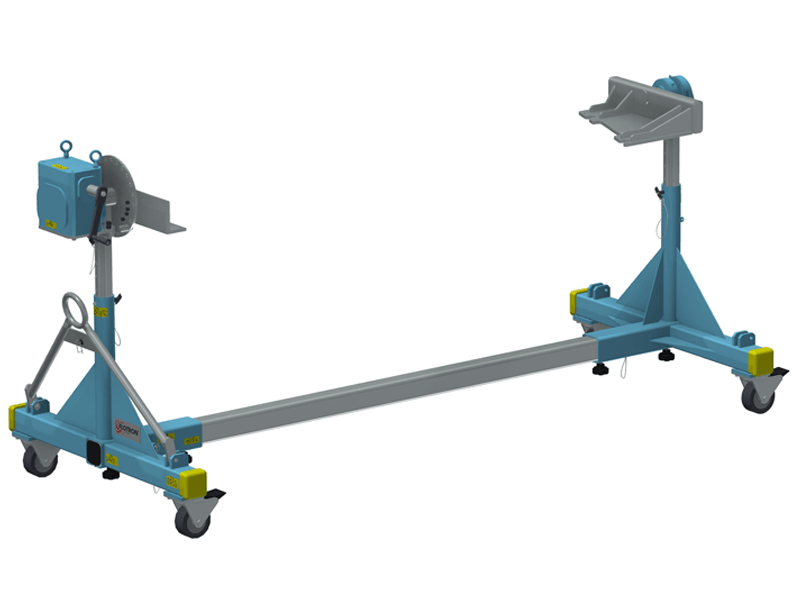

DSC-P2

(Hand Turned/Pinned Interface)

Load Rating: 2,500 lbs Cantilevered 30” (See dimensional drawing sheets 3-6 for load curves)

Payload Max Swing Radius: 59”

Max Torque (Secondary Axis): 10,000 in-lbs

Product Features

- Safety Factor: 3 for Yield & 5 for Ultimate

- Rated Load Capacity: Dynamic, 0″ to 4″ eccentricity: 2,500 lbs. (1,134 kg.) Cantilevered 30” (762mm)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Materials: Steel and aluminum construction. Stainless steel fasteners.

- Dual Pinned Interface: Redundant Pins for safety, one spring loaded, one ball lock pin to prevent interface rotation. Interface must be in payload vertical orientation (interface surface parallel to floor as shown) before removing rotation lock pins. Pins cannot be removed in any other orientation.

- Adjustable Interface Height: Eight bolt positions to ensure that payload CG is close to primary axis of rotation centerline. Four lift points integrated into frame for bolt position adjustment or for lifting empty cradle. Guide blocks included to facilitate adjustment.

- Optimized Design: Cradle analyzed with FEA to optimize design to be high capacity yet light weight.

Standard Configuration (For additional options click on “Configure a Flotron Cradle” button above or view dimensional drawing for detailed information)

- Finishes/Lubricants: Class 10k (ISO 7 cleanroom compatible finishes) – Cradle powder coated textured Flotron blue color; stainless steel hardware; aluminum parts chem film or hard anodized; Mobiltac 375NC (or equivalent) to all slewing ring teeth; slewing ring inner raceway lubricated with Mobilux EP2 (or equivalent). Fasteners lubricated with Loctite 242 blue or Krytox GPL 207.

- Cradle Length: 120” Between Mounting Interfaces. (Special cradle lengths available in 20” increments from standard).

Interface Bolt Pattern: ESPA Grande/MLB interface. 36X ¼-28 UNF threaded holes on a Ø24” bolt circle.

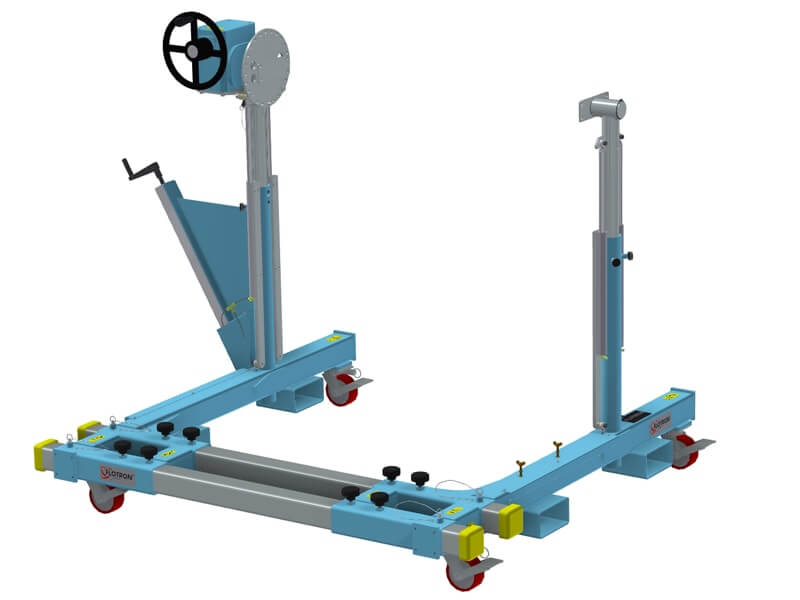

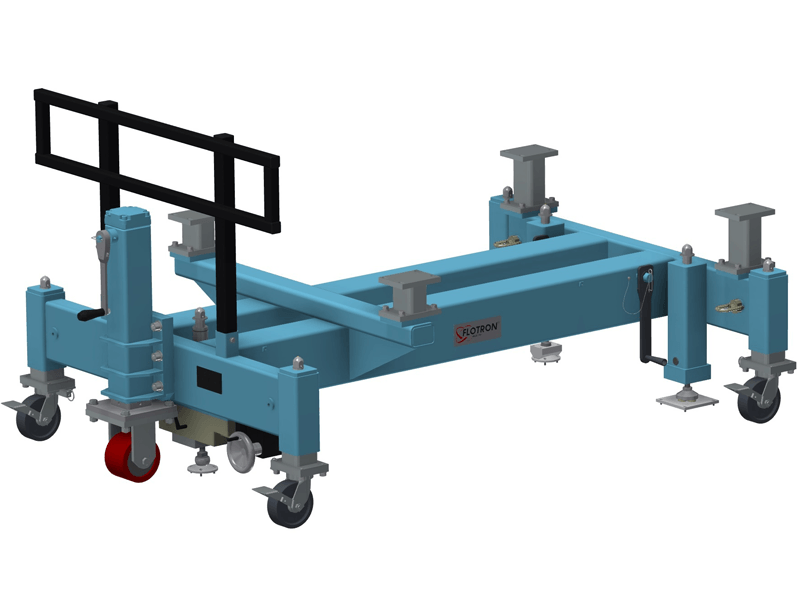

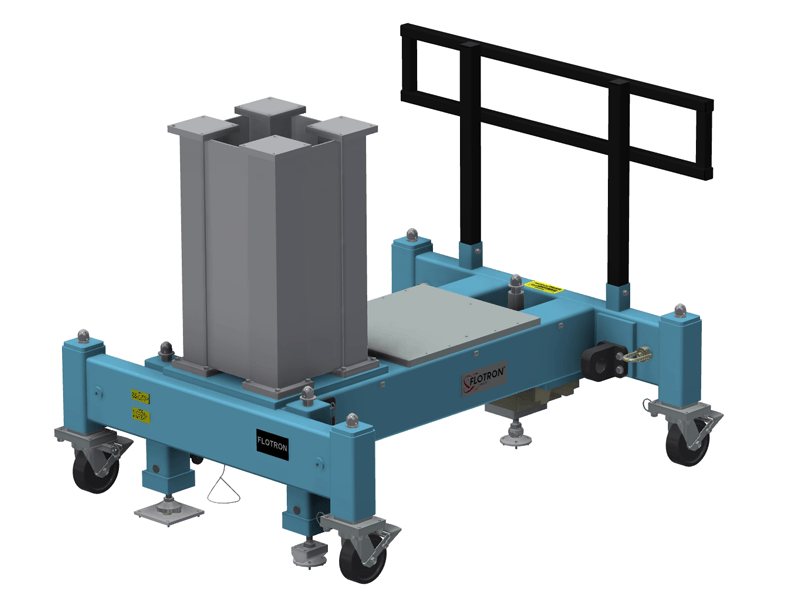

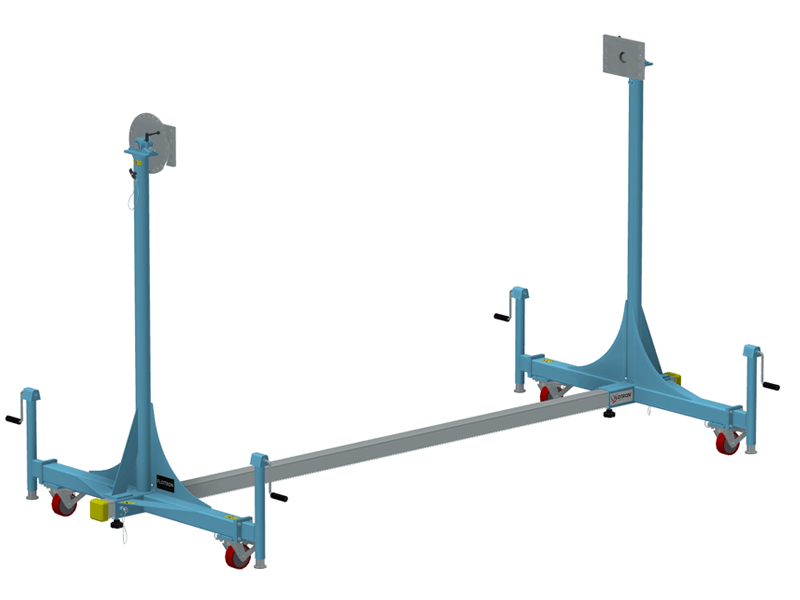

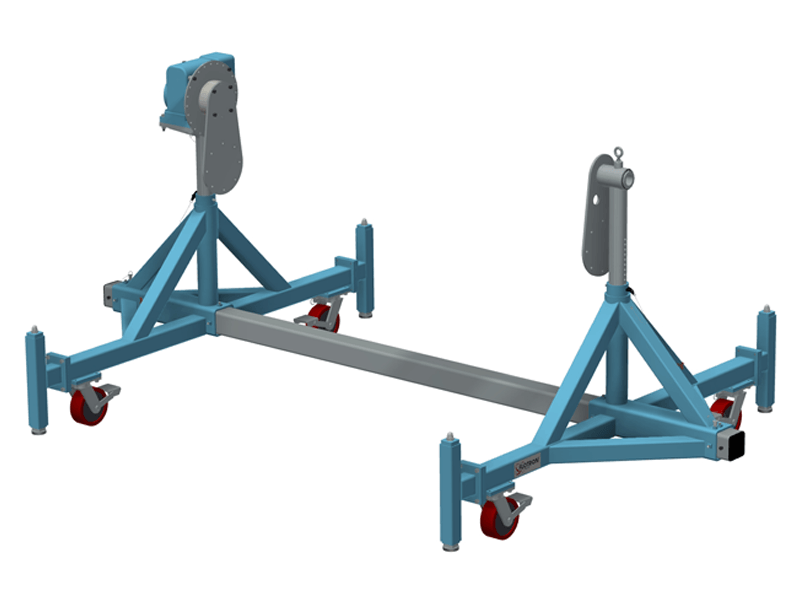

DSC-P1

(Hand Turned/Pinned Interface)

Load Rating: 700 lbs Cantilevered 24”

(See dimensional drawing sheets 3-6 for load curves)

Payload Max Swing Radius: 29”

Max Torque (Secondary Axis): 10,000 in-lbs

Product Features

- Safety Factor: 3 for Yield & 5 for Ultimate

- Rated Load Capacity: Dynamic, 0″ to 4″ eccentricity: 700 lbs. (317 kg.) Cantilevered 24” (609mm)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Materials: Steel and aluminum construction. Stainless steel fasteners.

- Dual Pinned Interface: Redundant Pins for safety, one spring loaded, one ball lock pin to prevent interface rotation. Interface must be in payload vertical orientation (interface surface parallel to floor as shown) before removing rotation lock pins. Pins cannot be removed in any other orientation.

- Adjustable Interface Height: Eight bolt positions to ensure that payload CG is close to primary axis of rotation centerline. Four lift points integrated into frame for bolt position adjustment or for lifting empty cradle. Guide blocks included to facilitate adjustment.

- Optimized Design: Cradle analyzed with FEA to optimize design to be high capacity yet light weight.

Standard Configuration (For additional options click on “Configure a Flotron Cradle” button above or view dimensional drawing for detailed information)

- Finishes/Lubricants: Class 10k (ISO 7 cleanroom compatible finishes) – Cradle powder coated textured Flotron blue color; stainless steel hardware; aluminum parts chem film or hard anodized; Mobiltac 375NC (or equivalent) to all slewing ring teeth; slewing ring inner raceway lubricated with Mobilux EP2 (or equivalent). Fasteners lubricated with Loctite 242 blue or Krytox GPL 207.

- Cradle Length: 60” Between Mounting Interfaces. (Special cradle lengths available in 20” increments from standard).

Interface Bolt Pattern: ESPA Grande/MLB interface. 36X ¼-28 UNF threaded holes on a Ø24” bolt circle.