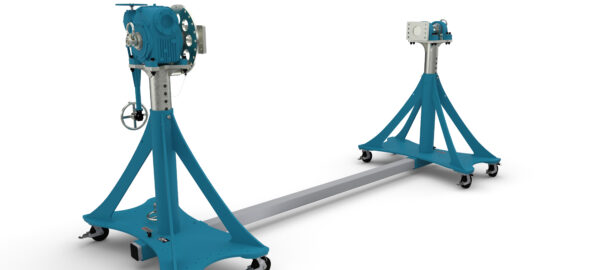

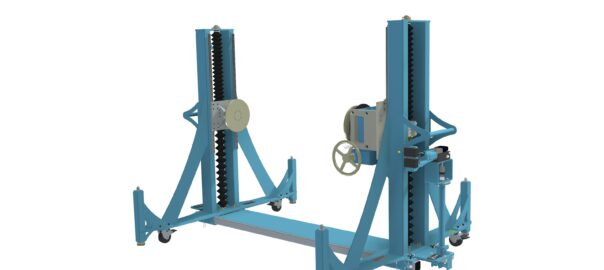

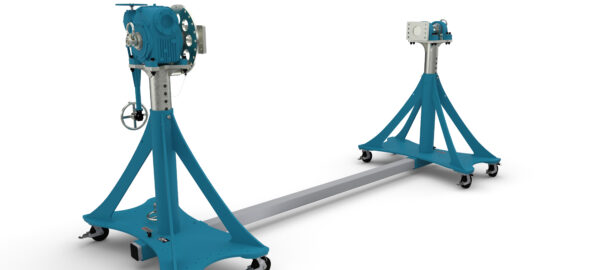

Flotron’s Small Foot Print (SFP) 1000 series Rotation Fixtures are a higher capacity, more compact version of the 1000 series where floor space is a premium. The SFP-1000 series includes additional features and options; lift points above the CG capable of lifting the Flotron (with the payload integrated), one inch of axial float on the non-gearbox side trunnion to ease payload integration, flat leg design to lower the rotation centerline height without sacrificing available payload swing radius, lighter weight to ease maneuverability, elimination of single failure points for launch site compatibility, pillow block bearing bushings on the non-gearbox-side trunnion, as well as an option for a cordless hand drill to rotate the gearbox. They are supplied with a heavy-duty, hollow shaft, stairstep resistant gearboxes to handle large, off-center loads that may occur during assembly of the mounted payload. See below for data on the SFP-1000 series models and click on any image for additional information.

SFP-847 Data Sheet

The Model SFP-847-J0-P1-INDS15-P12-T3 shown below is typical and representative of the SFP-847 Models. For more information on specifying a holding fixture, see the SFP-800 SERIES OPTION page and SFP-800 SERIES CREATING A MODEL NUMBER pdf.

- The maximum distance between mounting interfaces is directly related to the main beam length. Specify the distance between mounting interfaces to be at or slightly longer than the length of the payload. The end frames can be adjusted inward to accommodate shorter length payloads, however the main beam(s) protruding beyond the end frames may result in a trip hazard. For more information see the SFP-800 SERIES OPTIONS page and SFP-800 SERIES CREATING A MODEL NUMBER pdf.

- A shorter than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”.

Product Features:

- Safety Factor: 3 for Yield & 5 for Ultimate

- Rated Load Capacity: Dynamic, 0″ to 3.75″ eccentricity: 3,200 lbs. (1,455 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Combination P12 Mounting Plate / Angle Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beam

- Gearbox: Low backlash, non-back-driving, stair-step resistant, hollow shaft design with 60:1 ratio and 12″ diameter hand crank

- Axial Float & Sleeve Bearing in Non-Gearbox Side Trunnion: The non-gearbox side trunnion has one inch of axial float to ease payload integration as well as a PTFE composite sleeve bearing to eliminate grease migration, increase bearing life and reduce friction.

- Casters: Ø6″ x 3″ wide Nylatron wheels, king-pin-less swivel bearings, brakes and swivel locks.

- Index Plate: Standard with 15° index plate and index stops

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius“.

- Optional ground lug and drag chain for use in electrostatically protected areas (EPA’s)

- Optional main beam lengths

- Optional leveling jacks

- Optional finishes for clean room compatibility

- Optional lubricants

- Optional forklift tubes

- Optional gearbox mounted push bar

- Optional gearbox ratios

- Optional towing interface

- Optional casters/steering bars

- Optional proof load test

- Optional battery powered hand drill mounted to gearbox input shaft

- For more about SFP-800 Series Options click here

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For SFP-800 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

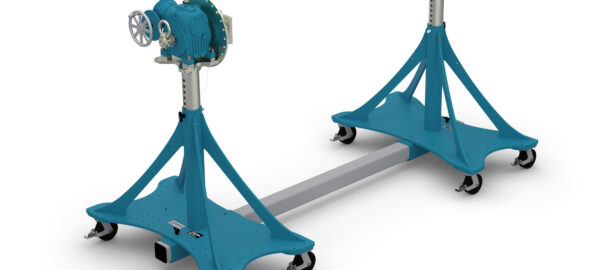

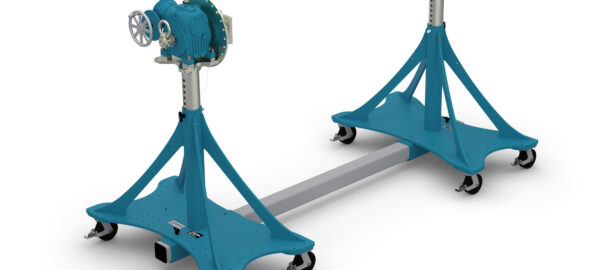

Flotron’s Small Foot Print (SFP) 900 series Rotation Fixtures are a higher capacity, more compact version of the 900 series where floor space is a premium. The SFP-900 series includes additional features and options; lift points above the CG capable of lifting the Flotron (with the payload integrated), one inch of axial float on the non-gearbox side trunnion to ease payload integration, flat leg design to lower the rotation centerline height without sacrificing available payload swing radius, lighter weight to ease maneuverability, elimination of single failure points for launch site compatibility, a needle roller bearing bushings on the non-gearbox-side trunnion, as well as an option for a cordless hand drill to rotate the gearbox. They are supplied with a heavy-duty, hollow shaft, stairstep resistant gearboxes to handle large, off-center loads that may occur during assembly of the mounted payload. See below for data on the SFP-900 series models and click on any image for additional information.

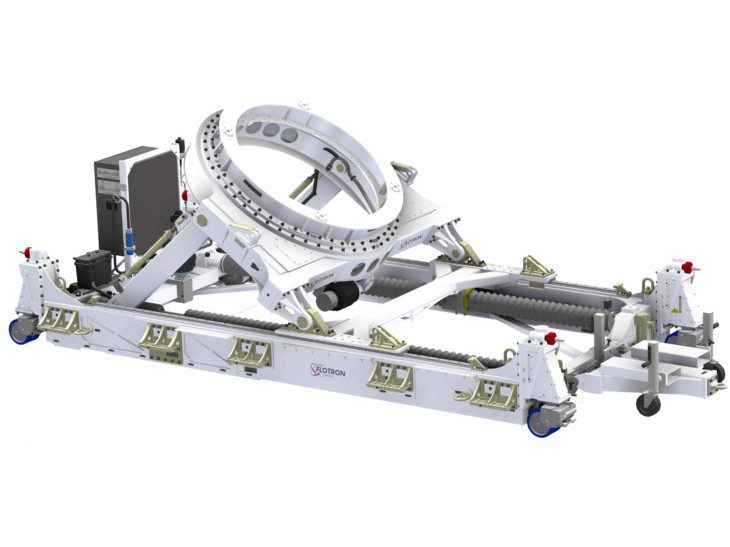

CRF129 Data Sheet

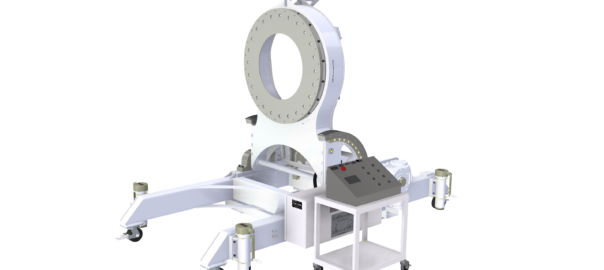

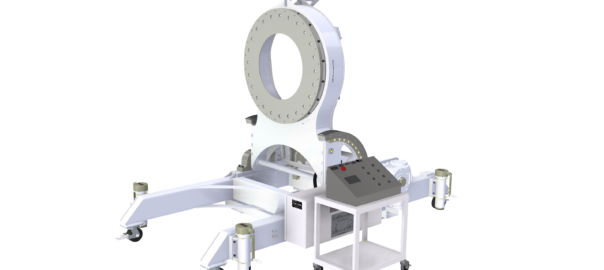

The Model CTL-C-129‐P56‐C10‐J1‐T1 shown below is typical and representative of the CTL129 Models. For more information on specifying a cantilevered rotation fixture, see the MID-SIZED SATELLITE FIXTURE OPTIONS page and MID-SIZED SATELLITE FIXTURE CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factors: 3 for Yield & 5 for Ultimate

- Primary Axis Rated Load Capacity: 12,000 lbs. with CG located at 90” from interface plate and 6” from primary axis rotation centerline.

- Optional Secondary Axis Rated Load Capacity: 7,000 lbs. with CG located at 110” from interface plate and 8” from secondary axis rotation centerline.

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Payload Interface: Ø56” Circular Interface Plate with 36X through holes for 5/8” fasteners on Ø48” bolt circle.

- Primary & Secondary Axis Gearbox/Slewing Ring: 3,204:1 total reduction. Inputs can be driven with a hand drill or 12″ diameter hand crank.

- Casters: Heavy duty 10″ diameter x 3.25″ wide nylatron wheel, sealed bearings, swivel lock, brake, and steering bar receptacles. (Ø12” diameter optional)

- Materials: Steel and aluminum construction.

- Finish: Clean room compatible finishes standard. Sky white powder coated frames; gearbox painted gloss white epoxy; nickel plated, black oxide or stainless-steel fasteners and miscellaneous hardware (no zinc).

- Optional Index Plate.

- Optional Casters.

- Optional Leveling Jacks.

- Optional Lubricants.

- Optional Tow Bar.

- Optional Secondary Axis of Rotation Structure

- Optional Standard Proof Load Test

- For more about Mid-Size Satellite Fixture Options click here.

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For Mid-Size Satellite Fixtures – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

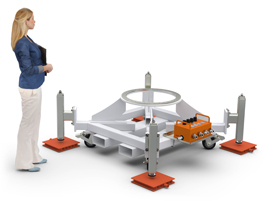

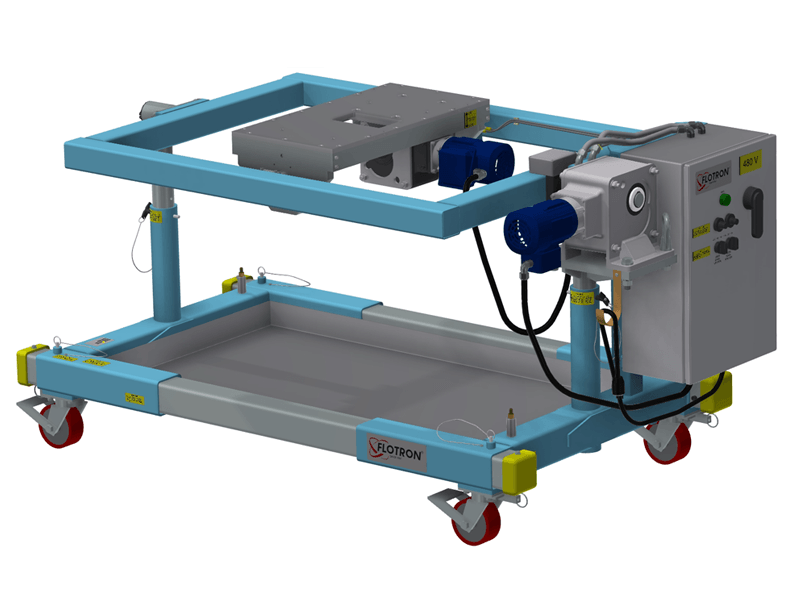

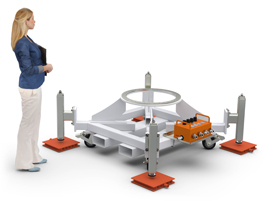

Flotron’s satellite mobile platforms are designed to support satellites in the vertical orientation, i.e. when the longitudinal axis of the satellite is perpendicular to the floor. The payload separation plane is low to the floor to minimize the required hook height when integrating the space vehicle with the platform interface using an overhead crane. The platform provides a working area for technicians to gain ergonomic access to the spacecraft during assembly, integration and test operations. Leveling jacks allow the technician to level the unit on uneven terrain. The satellite platform is designed to consider ergonomics during intra-facility transportation of the space vehicle. Caster wheel material has been specified to maximize rollability and both a push bar and a tow bar have been incorporated to provide options for maneuvering the loaded satellite mobile platform.

See below for comparative data on the satellite mobile platform models and click on any image for additional information.

Flotron’s Mobile Two Axis Positioner (MTAP-4000) allows for ergonomic tilting and rotation of the spaceflight hardware while being supported in a cantilevered configuration. The positioner can tilt 90 degrees from horizontal to vertical, or vice versa. The positioner can also rotate the hardware 360 degrees along its longitudinal axis utilizing a two axis UL approved control system. Over-travel limit switches have been incorporated at both ends of the tilt range. The interface has through access which may support propulsion integration or wiring.

The cart can support a 4,000 lb payload with CG located at 60” from the mounting interface and 5” from the rotation centerline considering a ½G side load and 1 G vertical load and SFy = 3 / SFu = 5. Two mechanically synchronized low backlash, non-back driving gearboxes are used for tilting, each of which is capable of supporting the rated moment. The H-frame design provides ergonomic access from either end of the fixture. The maximum available swing envelope is 110”. There are forklift tube pockets for lifting the empty fixture. The positioner is compatible in a Class 1K (ISO 6) clean room.

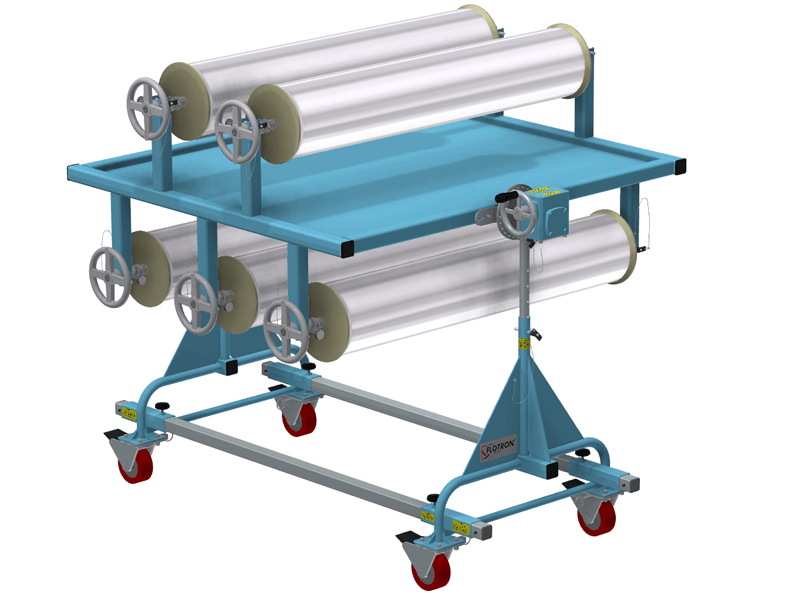

Flotron’s Mechanically Synchronized Lift/Rotate (MSL-2000) fixture has a load rating of 2,000 lbs at 3.75” maximum eccentricity considering SFy = 3 and SFu = 5 in addition to a simultaneous dynamic loading condition of ½ G side load and 1G vertical load.

Mechanically synchronized ACME screw lift jacks raise the carriages with bearing blocks along precision linear guide bearings rails through a 24” range. Hard stops limit the travel to prevent damage to the payload and a safety clutch has been incorporated to prevent damage to the power transmission. A +/- 1.0” axial float on the non-gearbox-side trunnion provides interface distance adjustment and allows for ergonomic payload integration and removal. Hard mounted battery powered drill drive lift/lower standard.

Discover Our Latest Innovations: New Products Available Now

We’re excited to introduce the latest additions to our portfolio of off-the-shelf products and product options, all available now in the products section of our website. We’ve been hard at work expanding our offerings to better serve your needs. Explore our fresh arrivals and discover how Flotron can provide you with even more innovative solutions for your projects. Stay tuned for more exciting updates as we continue to grow and evolve to meet your requirements.