Archives

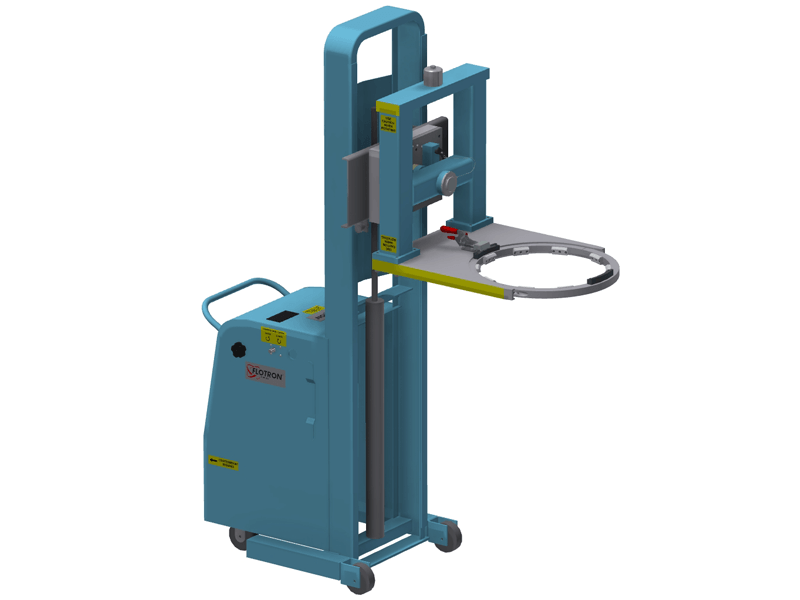

Cantilevered Rotation Fixtures

Flotron’s off‐the‐shelf cantilevered rotation fixture is designed to be a cost-effective solution to allow ergonomic full access to cantilevered payloads. The CRF design intent is to support small satellites or satellite instruments during assembly, integration and test activities. The spaceflight hardware can be supported in a cantilevered orientation so that the longitudinal axis is parallel to the floor and then rotated 360 degrees.

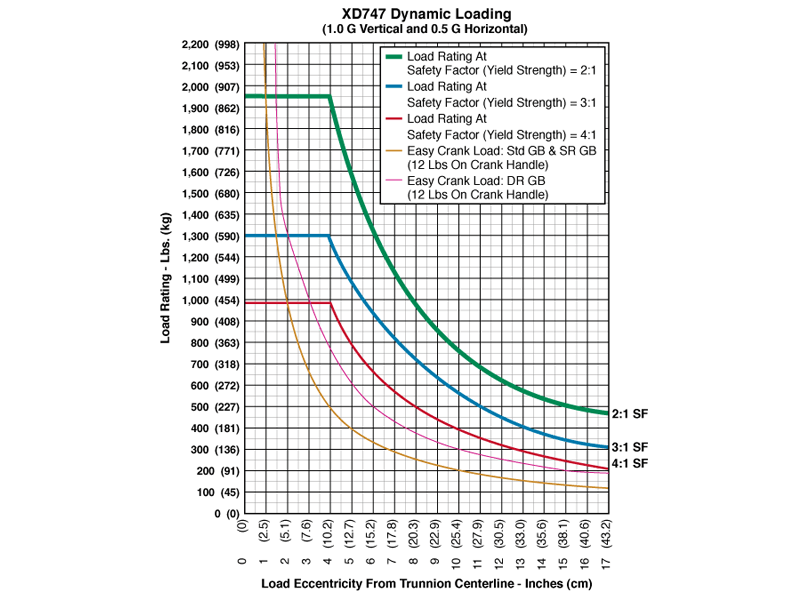

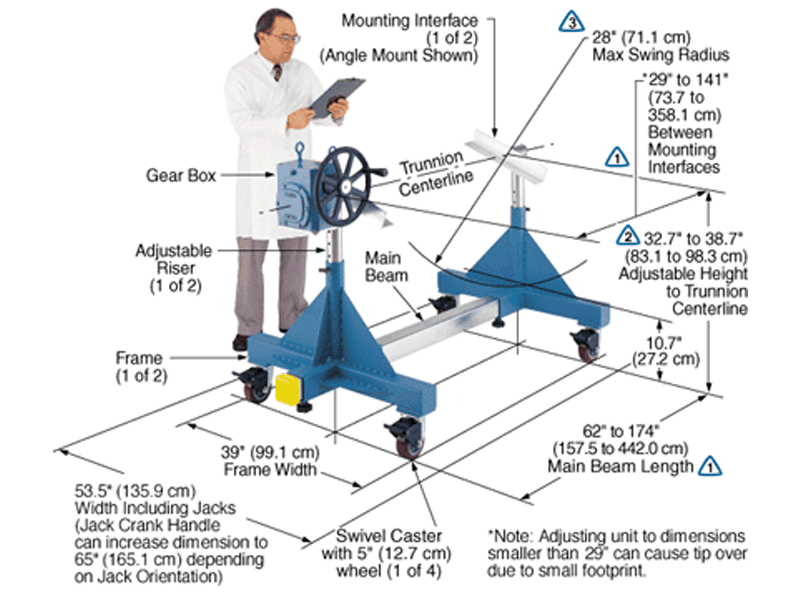

XD747

XD747 Data Sheet

The Model XD747-P8-B052 shown below is typical and representative of the XD747 Models. For more information on specifying a holding fixture, see the 700 SERIES OPTIONS page and 700 SERIES CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ eccentricity: 1,300 lbs. (590 kg.)

- Dynamic, 5″ eccentricity: 1,080 lbs. (490 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Choice of Trunnion Interface/Mount/Clamp Options:

- Angle Interface

- Mounting Plate Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beams

- Gearbox: 60:1 ratio with 12″ diameter crank

- Casters: 5″ diameter x 2″ wide wheel with polyurethane tread, sealed swivel bearing and Tech-lock brake

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

- Optional Main Beam lengths

- Optional Trunnion Interface/Mount/Clamp

- Optional Index Plate

- Optional Index Stops

- Optional Casters

- Optional Leveling Jacks

- Optional Gearboxes incorporating heavy duty, low backlash and stairstep resistant features

- Optional finishes for clean room compatibility

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- For more about 700 Series Options click here

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 700 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

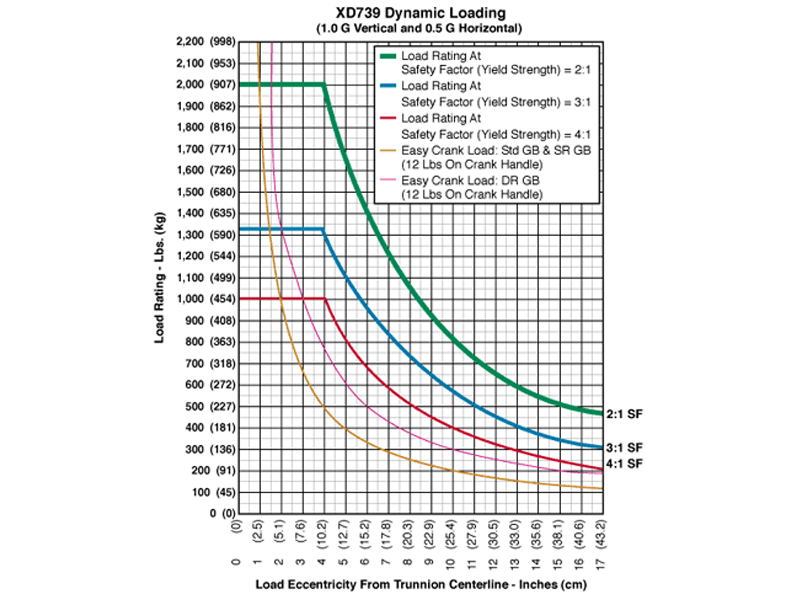

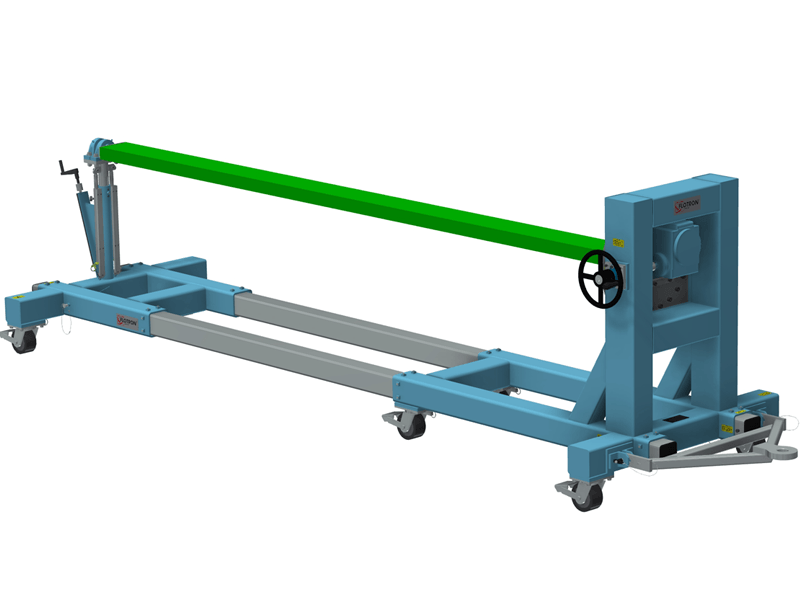

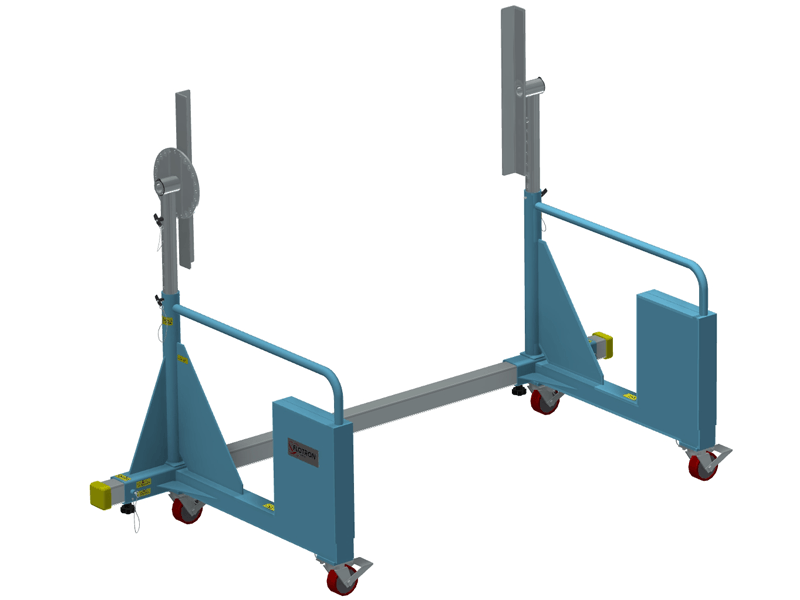

XD739

XD739 Data Sheet

The Model XD739-A18-B043 shown below is typical and representative of the XD739 Models. For more information on specifying a holding fixture, see the 700 SERIES OPTIONS page and 700 SERIES CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factor: 3

- Rated Load Capacity:

- Dynamic, 0″ eccentricity: 1,330 lbs. (603 kg.)

- Dynamic, 5″ eccentricity: 1,080 lbs. (490 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Choice of Trunnion Interface/Mount/Clamp Options:

- Angle Interface

- Mounting Plate Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beams

- Gearbox: 60:1 ratio with 12″ diameter crank

- Casters: 5″ diameter x 2″ wide wheel with polyurethane tread, sealed swivel bearing and Tech-lock brake

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”

- Optional Main Beam Lengths

- Optional Trunnion Interface/Mount/Clamp

- Optional Index Plate

- Optional Index Stops

- Optional Casters

- Optional Leveling Jacks

- Optional Gearboxes incorporating heavy duty, low backlash and stairstep resistant features

- Optional finishes for clean room compatibility

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s)

- For more about 700 Series Options click here

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For 700 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

Dual Support Cradles

Flotron’s Dual Support Cradles (DSC) are designed to turn a standard rotation fixture into a dual axis of rotation fixture. The DSC is for cantilevered payloads that require both tilting and 360° rotation. There are different capacity cradles for different payload weights and the larger cradle features the option to have gearbox driven rotation on the secondary axis of rotation. The DSC-P1 was designed to be used with Flotron’s XD739, XD747, or SFP-645 series dual support fixtures. The DSC-P2 and DSC-G2 were designed to be used with Flotron’s SFP-759, SFP-853, or SFP-862 series dual support fixtures. The cradles can be used with other rotation fixtures if the capacity is rated high enough and swing clearance is sufficient. The cradles have been optimized for both high strength and low weight with advanced FEA software. Custom length cradles are available upon request in 20” increments for payloads that require more (or less) swing radius clearance than the standard. The load rating may be lower for longer cradles than standard.

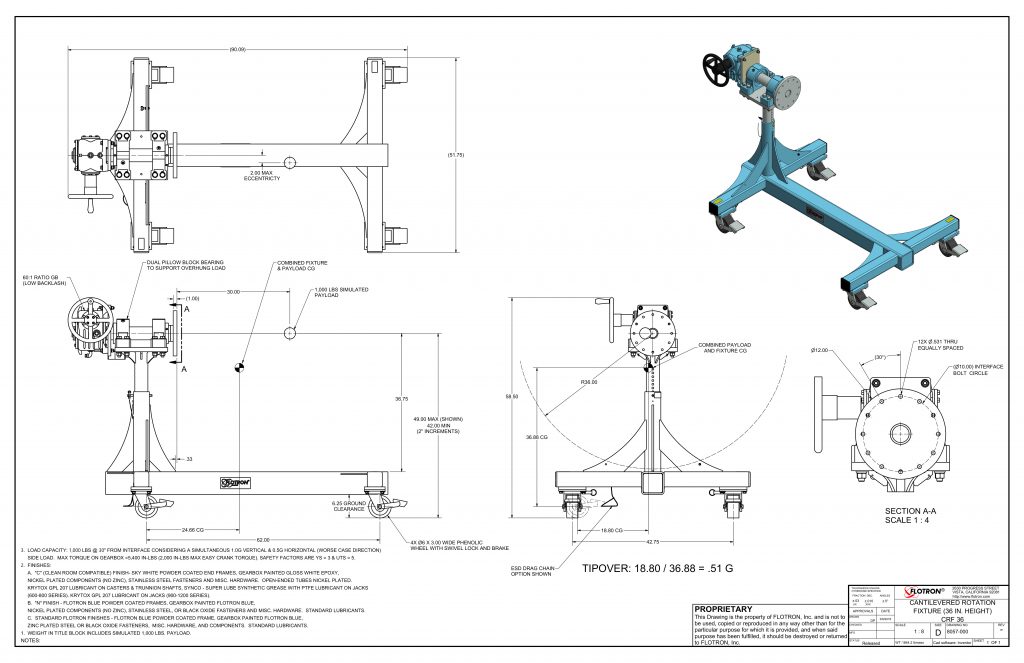

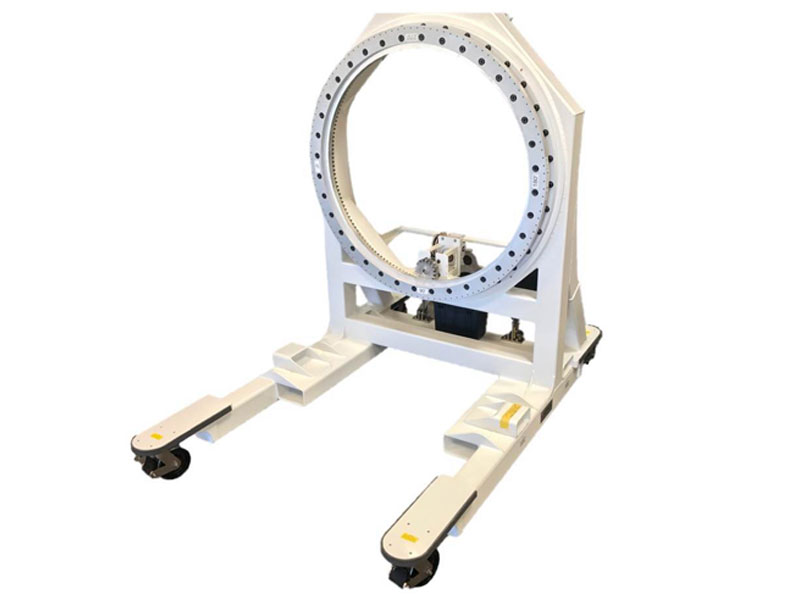

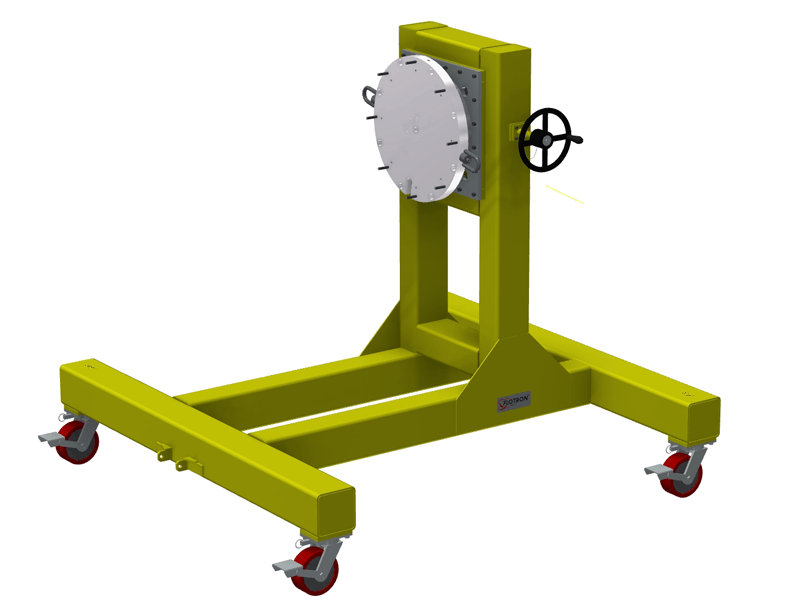

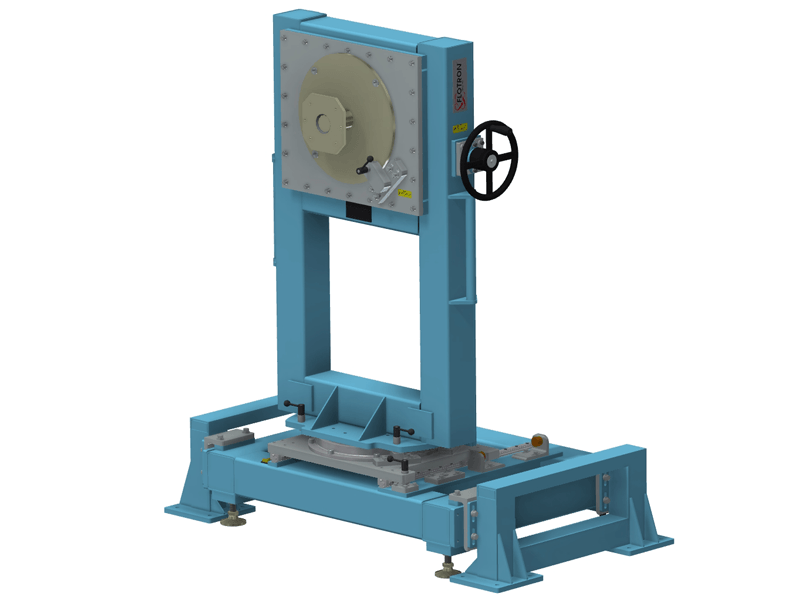

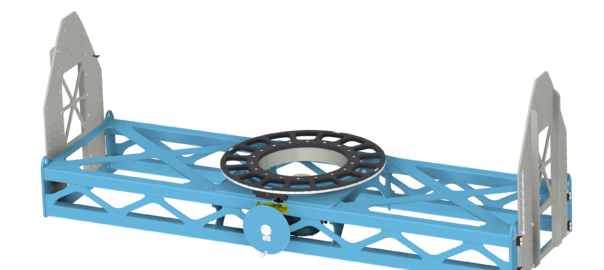

CRF 36

CRF 36 Data Sheet

The Model CRF-36‐P12‐C6 shown below is typical and representative of the CTL 36 Models. For more information on specifying a cantilevered rotation fixture, see the CANTILEVERED ROTATION FIXTURE page and CANTILEVERED ROTATION FIXTURE CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factors: 3 for Yield & 5 for Ultimate

- Rated Load Capacity: 1,000 lbs. with CG located at 30” from interface plate and 2” from primary axis rotation centerline.

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Payload Interface: Ø12” Circular Interface Plate with 12X through holes for 1/2” fasteners on Ø10” bolt circle.

- Gearbox: 60:1ratio with 12” diameter crank.

- Casters: Heavy duty 6″ diameter x 3″ wide phenolic tread, sealed bearings, swivel lock, brake, and steering bar receptacles. (Ø12” diameter optional)

- Materials: Steel construction.

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- Optional Casters.

- Optional Lubricants.

- Optional Tow Bar.

- Optional finishes for clean room compatibility.

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s).

- Optional Standard Proof Load Test.

- For more about Cantilevered Rotation Fixture Options click here.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For Cantilevered Rotation Fixtures – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

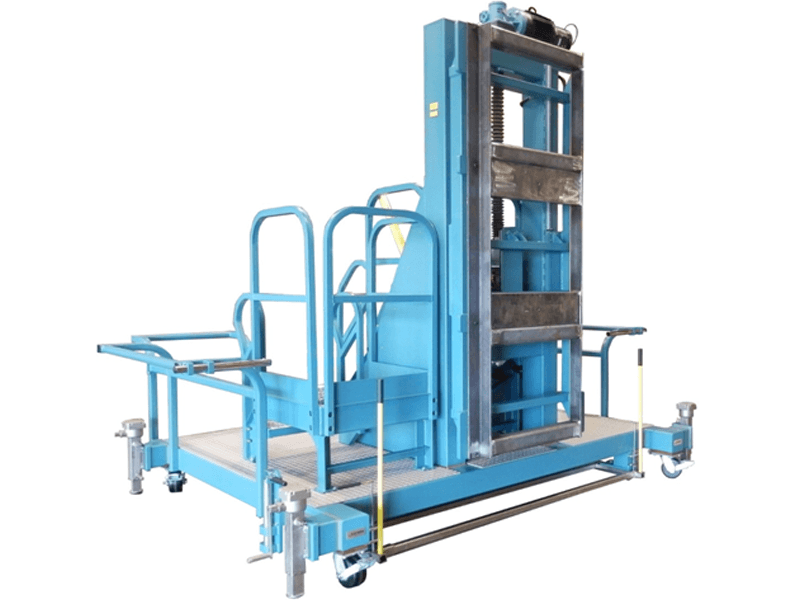

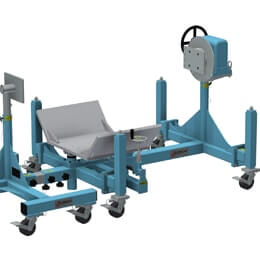

Integration Fixtures

Cantilevered

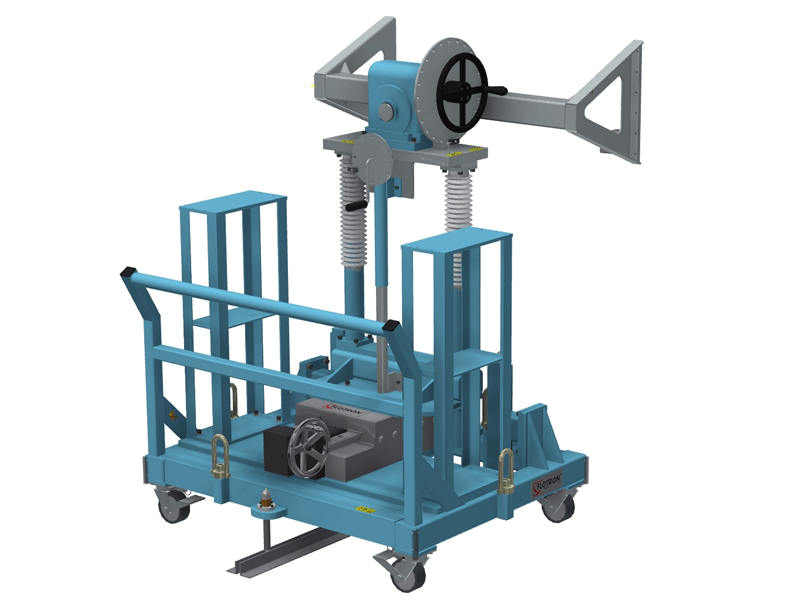

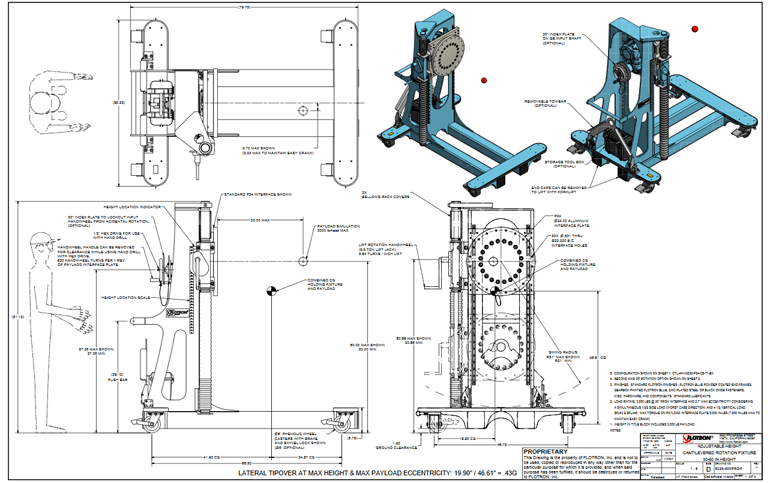

CTL-AH

CTL-AH Data Sheet

The Model CTL‐AH‐P24‐C6‐T1‐BX shown below is typical and representative of the CTL‐AH Models. For more information on specifying a cantilevered rotation fixture, see the SMALL SATELLITE FIXTURE OPTIONS page and SMALL SATELLITE FIXTURE CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factor: 3

- Rated Load Capacity: 3,000 lbs with CG located at 30” from interface plate and 2.7” from rotation centerline.

- Lift Range: 30”‐60” from floor to center of rotation.

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Payload Interface: Ø24” Circular Interface Plate with 20X through holes for 1⁄2” fasteners on Ø22” bolt circle.

- Gearbox: 175:1 ratio with 8′′ diameter crank.

- Slewing Ring: 3.6:1 ratio.

- Rack and Pinion Jack: 5.64 turns per inch lift.

- Casters: Heavy duty 6′′ diameter x 3′′ wide wheel with phenolic tread, sealed swivel bearing. Tech‐lock brake and swivel locks. (8” diameter optional).

- Materials: Steel and aluminum construction.

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- Optional Index Plate.

- Optional Casters.

- Optional Tow Bar.

- Optional Tool Box.

- Optional finishes for clean room compatibility.

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s).

- For more about Small Satellite Fixture Options click here.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For Small Satellite Fixture – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

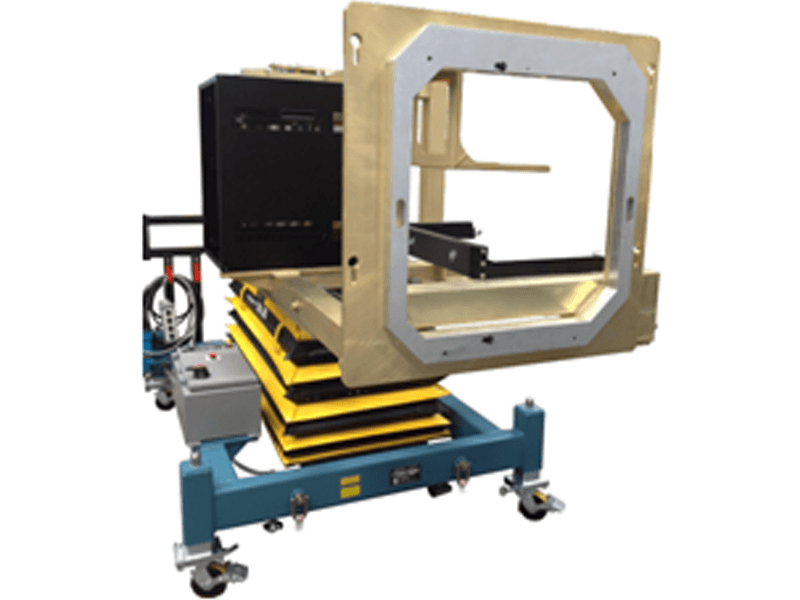

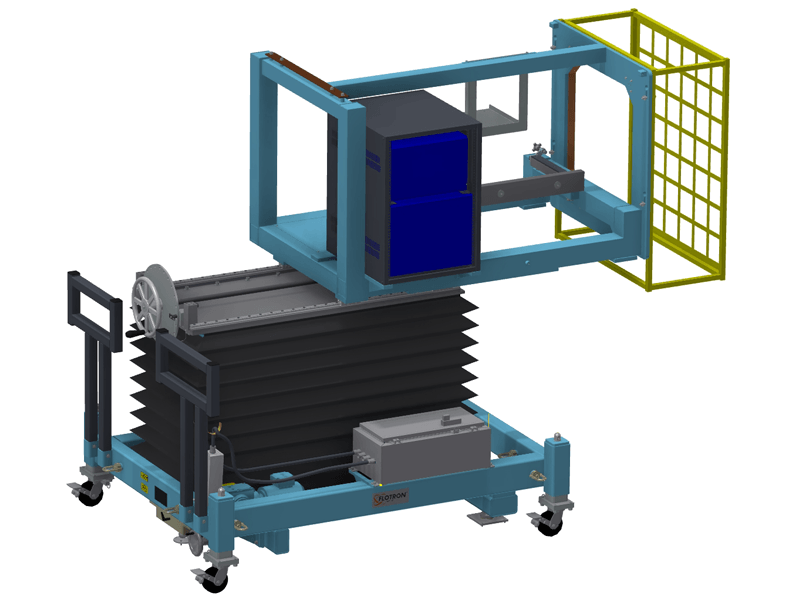

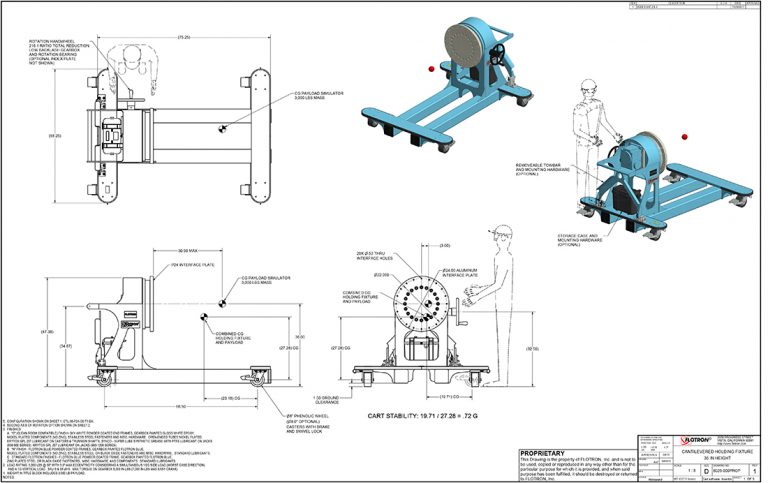

CTL36

CTL36 Data Sheet

The Model CTL36‐P24‐C6‐T1‐BX shown below is typical and representative of the CTL36 Models. For more information on specifying a cantilevered rotation fixture, see the SMALL SATELLITE FIXTURE OPTIONS page and SMALL SATELLITE FIXTURE CREATING A MODEL NUMBER pdf.

Product Features:

- Safety Factor: 3

- Rated Load Capacity: 3,000 lbs with CG located at 30” from interface plate and 2.6” from rotation centerline.

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Trunnion Interface/Mount/Clamp Options: Ø24” Circular Interface Plate with 20X through holes for ½” fasteners on Ø22” bolt circle.

- Gearbox: 60:1 ratio with 12″ diameter crank.

- Casters: Heavy duty 6″ diameter x 3″ wide wheel with phenolic tread, sealed swivel bearing. Tech‐lock brake and swivel locks.

- Materials: Steel construction.

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- Optional Index Plate.

- Optional Casters.

- Optional Tow Bar.

- Optional Tool Box.

- Optional finishes for clean room compatibility.

- Optional Ground Lug and Drag Chain for use in electrostatically protected areas (EPA’s).

- For more about Small Satellite Fixture Options click here.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For Small Satellite Fixture – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.