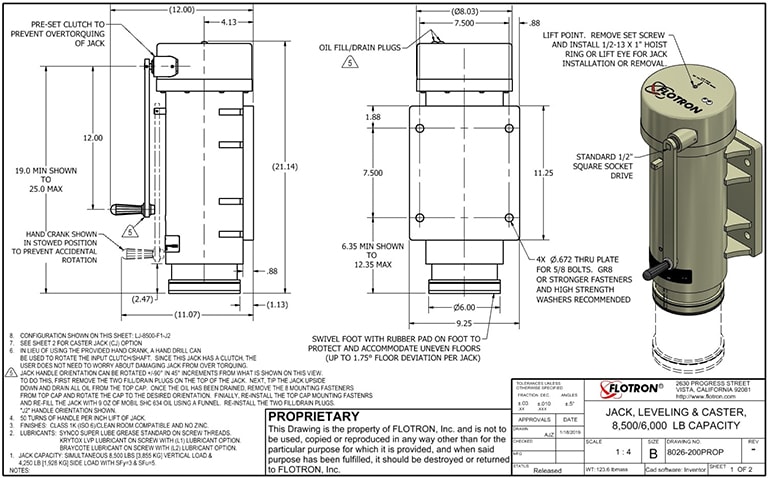

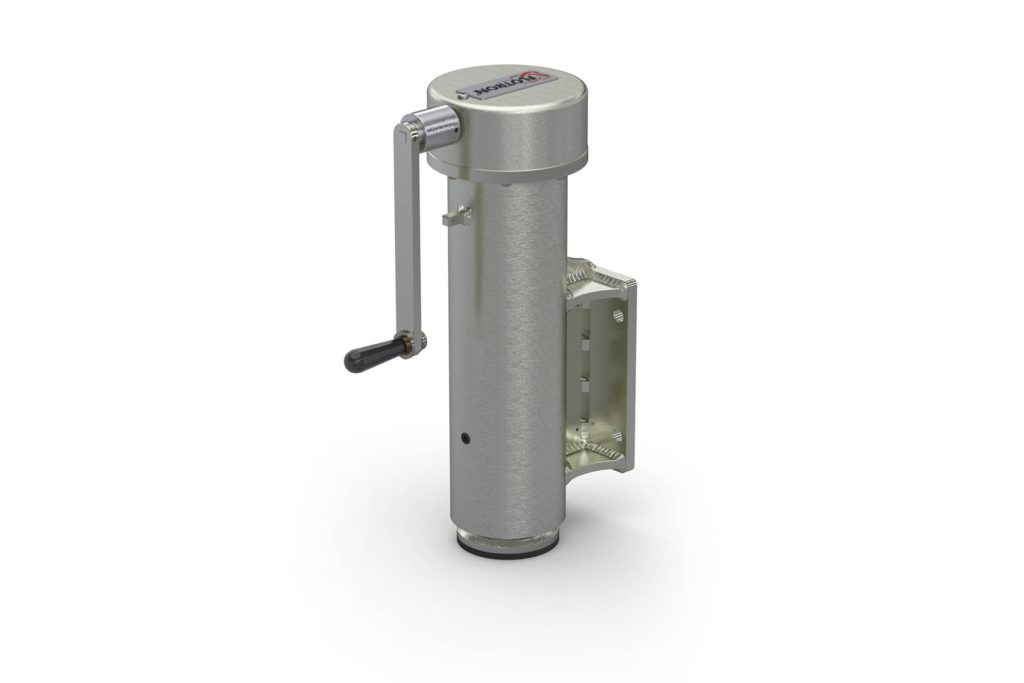

LJ-8500 Data Sheet

The Model LJ-8500 shown below is typical and representative of the LJ-8500 Models. For more information on specifying a jack, see the JACK OPTIONS page and JACK CREATING A MODEL NUMBER pdf.

Click on Leveling Jack image for an Interactive experience

[dcb name=styling-click-for-experience-text]

Product Features:

- Safety Factors: SFy=3 and SFu=5

- Rated Load Capacity: Simultaneous 8,500 lbs. (3,855 kg.) vertical load and 4,250 lb (1,928 kg.) side load in any direction.

- Operating Temperature: +32° to +104°F (0 to +40 °C). Contact Flotron for special applications with extended operating temperatures.

- Hand Crank: 12″ long removable crank to reveal a 1/2″ square drive input. When the handle is removed, the jack can be raised/lowered with a standard hand drill (300 rpm max non-impact)

- Input Clutch: Pre-set at Flotron to prevent damage to the jack at the end of travel.

- Turns per inch lift: 50 turns of handle per inch lift of jack.

- Materials: Steel and aluminum construction. Stainless steel fasteners. Bronze nut.

- Finish: Steel and Aluminum parts nickel plated.

- Lubricants: Synco super lube grease standard on screw threads. All other bearings or gears are either self-lubricating or sealed. For additional lubricant options, click here

- Leveling Foot: Leveling foot with rubber pad on bottom of jack ram for severely uneven floors. Leveling foot accommodates 1.75° floor deviation per jack.

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For Jack – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

Coming Soon: Sneak Peek into Our Product Developments in Progress

Explore Flotron’s Product Development Section where we are diligently creating the next generation of “Off-the-shelf” products. You’ll find an array of designs, many of which are nearing completion or are versions of custom solutions that we’re eager to transform into readily available products. If you spot something that aligns with your needs, please don’t hesitate to reach out to our sales team for more information and updates on the development progress. Your feedback and interest are invaluable as we continue to innovate and expand our product offerings.

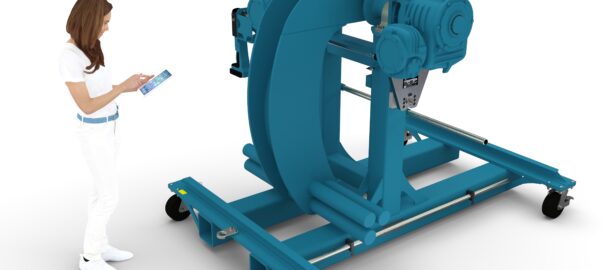

Flotron’s Satellite Upender (SU-2500) can rotate 90 degrees from horizontal to vertical, or vice versa to allow for solar array deployment, satellite integration, or pass through hallways and doorways among other applications. There are counterweights to reduce the load on the gearboxes. The SU-2500 allows for ergonomic transportation of small satellites during their move through a customer’s facility.

The cart can support a 2,500 lb payload with a 30” CG offset from the interface plate. A hard stop with audible alarms limits the travel to prevent damage to the payload. Custom modifications are available; however, stability and keep out zones will limit the design. The upender will have optional fixed interface or pinned second axis of rotation.

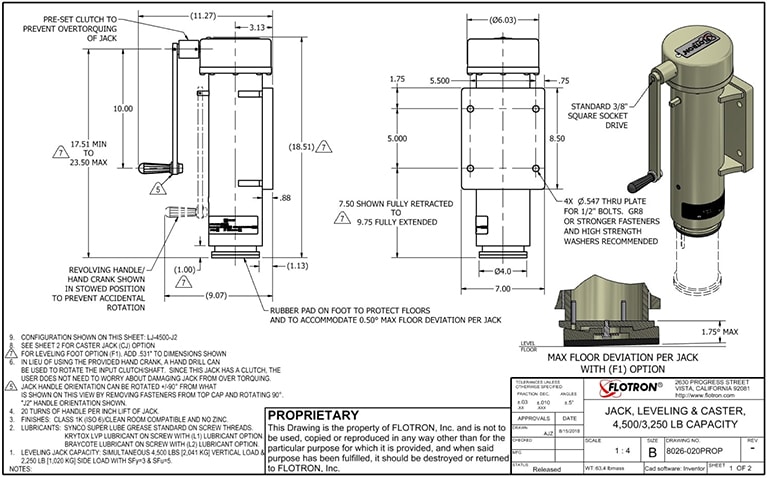

LJ-4500 Data Sheet

The Model LJ-4500 shown below is typical and representative of the LJ-4500 Models. For more information on specifying a jack, see the JACK OPTIONS page and JACK CREATING A MODEL NUMBER pdf.

Click on Leveling Jack image for an Interactive experience

[dcb name=styling-click-for-experience-text]

Product Features:

- Safety Factors: SFy=3 and SFu=5

- Rated Load Capacity: Simultaneous 4,500 lbs. (2,041 kg.) vertical load and 2,250 lb (1,020 kg.) side load in any direction.

- Operating Temperature: +32° to +104°F (0 to +40 °C). Contact Flotron for special applications with extended operating temperatures.

- Hand Crank: 10″ long removable crank to reveal a 3/8″ square drive input. When the handle is removed, the jack can be raised/lowered with a standard hand drill (300 rpm max non-impact). For hand crank orientation options click here

- Input Clutch: Pre-set at Flotron to prevent damage to the jack at the end of travel.

- Turns per inch lift: 20 turns of handle per inch lift of jack.

- Materials: Steel and aluminum construction. Stainless steel fasteners. Bronze nut.

- Finish: Steel and Aluminum parts nickel plated.

- Lubricants: Synco super lube grease standard on screw threads. All other bearings or gears are either self-lubricating or sealed. For additional lubricant options, click here

- Leveling Foot: The standard jack has a rubber pad on bottom of jack ram to accommodate 0.50° max floor deviation per jack. For additional leveling foot options for severely uneven floors, click here.

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For Jack – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

Flotron’s Satellite Upender (SU-1000) allows for ergonomic transportation of small satellites during their move through a customer’s facility. The SU-1000 can rotate 90 degrees from horizontal to vertical, or vice versa to allow solar array deployment, satellite integration, or pass through hallways and doorways among other applications.

The cart can support a 1,000 lb payload with a 25” CG offset from the interface plate. A hard stop with audible alarms limits the travel to prevent damage to the payload. Custom modifications are available; however, stability and keep out zones will limit the design. The upender will have optional fixed interface or pinned second axis of rotation.

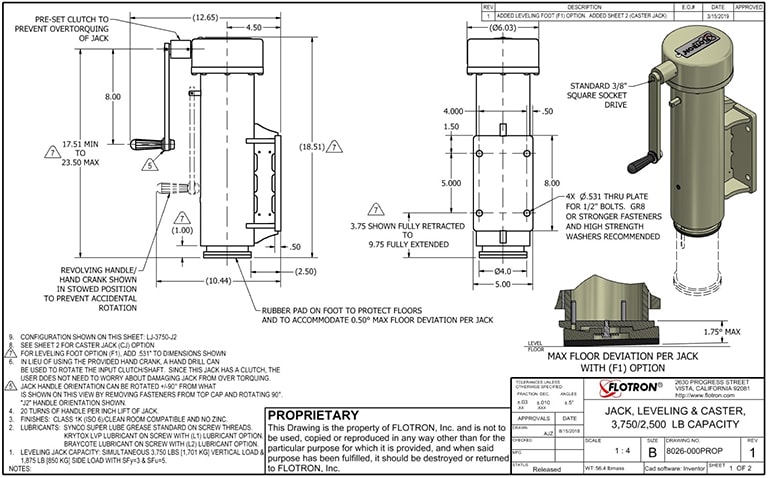

LJ-3750 Data Sheet

The Model LJ-3750 shown below is typical and representative of the LJ-3750 Models. For more information on specifying a jack, see the JACK OPTIONS page and JACK CREATING A MODEL NUMBER pdf.

Click on Leveling Jack image for an Interactive experience

[dcb name=styling-click-for-experience-text]

Product Features:

- Safety Factors: SFy=3 and SFu=5

- Rated Load Capacity: Simultaneous 3,750 lbs. (1,701 kg.) vertical load and 1,875 lb (850 kg.) side load in any direction.

- Operating Temperature: +32° to +104°F (0 to +40 °C). Contact Flotron for special applications with extended operating temperatures.

- Hand Crank: 8″ long removable crank to reveal a 3/8″ square drive input. When the handle is removed, the jack can be raised/lowered with a standard hand drill (300 rpm max non-impact). For hand crank orientation options click here

- Input Clutch: Pre-set at Flotron to prevent damage to the jack at the end of travel.

- Turns per inch lift: 20 turns of handle per inch lift of jack

- Materials: Steel and aluminum construction. Stainless steel fasteners. Bronze nut.

- Finish: Steel and aluminum parts nickel plated.

- Lubricants: Synco super lube grease standard on screw threads. All other bearings or gears are either self-lubricating or sealed. For additional lubricant options, click here

- Leveling Feet: The standard jack has a rubber pad on bottom of jack ram to accommodate 0.50° max floor deviation per jack. For additional leveling foot options for severely uneven floors, click here.

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For Jack – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

Flotron’s X-Shaped Satellite Mobile Stand (SMS-4000) is a Mobile Platform that is designed to support assembly, integration, test, and transportation activities. The SMS-4000 can support a 4,000 lbs payload with vertical CG located at up to 59” above the mounting interface and up to 5” out from the longitudinal axis of the payload. These ratings consider SFy = 3 and SFu = 5 in addition to a simultaneous dynamic loading condition of 0.5G horizontal (worst case direction) and 1.0G vertical. The horizontal stability is above 1/2G. Interface hole pattern is for a Ø24” ESPA Grande.

SFP-862 Data Sheet

The Model SFP-862-J0-P1-INDS15-P12-T3 shown below is typical and representative of the SFP-862 Models. For more information on specifying a holding fixture, see the SFP-800 SERIES OPTION page and SFP-800 SERIES CREATING A MODEL NUMBER pdf.

- The maximum distance between mounting interfaces is directly related to the main beam length. Specify the distance between mounting interfaces to be at or slightly longer than the length of the payload. The end frames can be adjusted inward to accommodate shorter length payloads, however the main beam(s) protruding beyond the end frames may result in a trip hazard. For more information see the SFP-800 SERIES OPTIONS page and SFP-800 SERIES CREATING A MODEL NUMBER pdf.

- A shorter than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”.

Product Features:

- Safety Factor: 3 for Yield & 5 for Ultimate

- Rated Load Capacity: Dynamic, 0″ to 3.75″ eccentricity: 3,200 lbs. (1,455 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Combination P12 Mounting Plate / Angle Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beam

- Gearbox: Low backlash, non-back-driving, stair-step resistant, hollow shaft design with 60:1 ratio and 12″ diameter hand crank

- Axial Float & Sleeve Bearing in Non-Gearbox Side Trunnion: The non-gearbox side trunnion has one inch of axial float to ease payload integration as well as a PTFE composite sleeve bearing to eliminate grease migration, increase bearing life and reduce friction.

- Casters: Ø6″ x 3″ wide Nylatron wheels, king-pin-less swivel bearings, brakes and swivel locks.

- Index Plate: Standard with 15° index plate and index stops

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius“.

- Optional ground lug and drag chain for use in electrostatically protected areas (EPA’s)

- Optional main beam lengths

- Optional leveling jacks

- Optional finishes for clean room compatibility

- Optional lubricants

- Optional forklift tubes

- Optional gearbox mounted push bar

- Optional gearbox ratios

- Optional towing interface

- Optional casters/steering bars

- Optional proof load test

- Optional battery powered hand drill mounted to gearbox input shaft

- For more about SFP-800 Series Options click here

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For SFP-800 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

SFP-853 Data Sheet

The Model SFP-853-J0-P1-INDS15-P12-T3 shown below is typical and representative of the SFP-853 Models. For more information on specifying a holding fixture, see the SFP-800 SERIES OPTION page and SFP-800 SERIES CREATING A MODEL NUMBER pdf.

- The maximum distance between mounting interfaces is directly related to the main beam length. Specify the distance between mounting interfaces to be at or slightly longer than the length of the payload. The end frames can be adjusted inward to accommodate shorter length payloads, however the main beam(s) protruding beyond the end frames may result in a trip hazard. For more information see the SFP-800 SERIES OPTIONS page and SFP-800 SERIES CREATING A MODEL NUMBER pdf.

- A shorter than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius”.

Product Features:

- Safety Factor: 3 for Yield & 5 for Ultimate

- Rated Load Capacity: Dynamic, 0″ to 3.75″ eccentricity: 3,200 lbs. (1,455 kg.)

- Operating Temperature: +32 to +104 °F (0 to +40 °C). Contact factory for special applications with extended operating temperatures.

- Combination P12 Mounting Plate / Angle Interface

- Choice of Main Beam Length

- Main Beam Ball Lock Pins: Reliably prevents End Frames from slipping on Main Beam

- Gearbox: Low backlash, non-back-driving, stair-step resistant, hollow shaft design with 60:1 ratio and 12″ diameter hand crank

- Axial Float & Sleeve Bearing in Non-Gearbox Side Trunnion: The non-gearbox side trunnion has one inch of axial float to ease payload integration as well as a PTFE composite sleeve bearing to eliminate grease migration, increase bearing life and reduce friction.

- Casters: Ø6″ x 3″ wide Nylatron wheels, king-pin-less swivel bearings, brakes and swivel locks.

- Index Plate: Standard with 15° index plate and index stops

- Materials: Steel construction

- Finish: Flotron Blue powder coat with selected parts zinc plated.

- A smaller than standard swing radius may be recommended for some applications. See the “Technical Section” under “Holding Fixture Safety” on page 3 of 7 concerning “Unexpected Accident Loads” and the chart on page 4 of 7 referring to “Maximum Recommended Swing Radius“.

- Optional ground lug and drag chain for use in electrostatically protected areas (EPA’s)

- Optional main beam lengths

- Optional leveling jacks

- Optional finishes for clean room compatibility

- Optional lubricants

- Optional forklift tubes

- Optional gearbox mounted push bar

- Optional gearbox ratios

- Optional towing interface

- Optional casters/steering bars

- Optional proof load test

- Optional battery powered hand drill mounted to gearbox input shaftt

- For more about SFP-800 Series Options click here

All data presented is based on no modifications to the product.

As Flotron is constantly improving products and methods of manufacturing, we reserve the right to modify and/or change design or specifications without notice. Please contact Flotron for verification of critical dimensions and specifications.

For SFP-800 Series – Creating a Model Number pdf click here.

For clarification of terms or phrases, please see the Holding Fixtures Definitions page.

Flotron’s Small Foot Print (SFP) 1000 series Rotation Fixtures are a higher capacity, more compact version of the 1000 series where floor space is a premium. The SFP-1000 series includes additional features and options; lift points above the CG capable of lifting the Flotron (with the payload integrated), one inch of axial float on the non-gearbox side trunnion to ease payload integration, flat leg design to lower the rotation centerline height without sacrificing available payload swing radius, lighter weight to ease maneuverability, elimination of single failure points for launch site compatibility, needle roller bearing bushings on the non-gearbox-side trunnion, as well as an option for a cordless hand drill to rotate the gearbox. They are supplied with a heavy-duty, hollow shaft, stairstep resistant gearboxes to handle large, off-center loads that may occur during assembly of the mounted payload. See below for data on the SFP-1000 series models and click on any image for additional information.